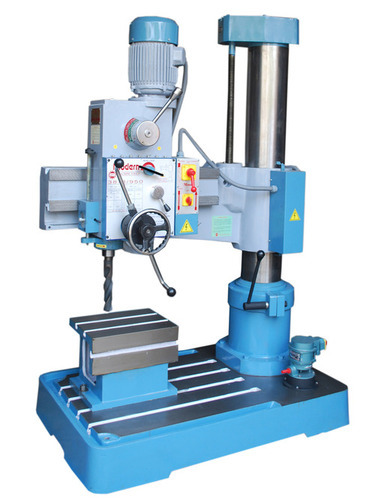

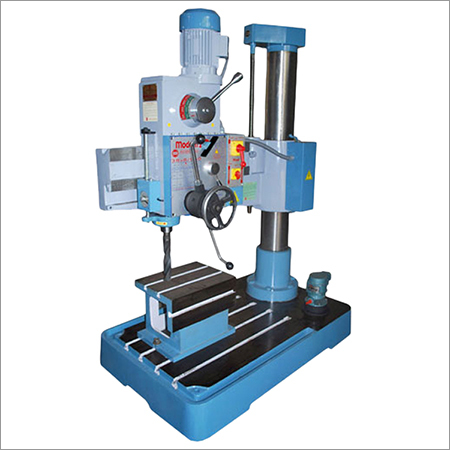

32 MM Radial Drill Machine

Price 85000 INR/ Unit

32 MM Radial Drill Machine Specification

- Spindle Speed

- 801500 RPM (variable)

- Cutting Area

- Up to 32 mm Dia

- Machine Type

- Radial Drill Machine

- Noise Level

- Low

- Frequency

- 50 Hz

- Condition

- New

- Features

- High precision, sturdy build, easy operation, adjustable arm movement, durable construction

- Table Size

- 450 x 350 mm

- Motor Power

- 1.5 HP

- Diameter

- 32 mm

- Product Type

- Radial Drill Machine

- Material

- Stainless Steel & Cast Iron

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- CNC Or Not

- No

- Control System

- Manual

- Voltage

- 220-380 Volt (v)

- Power

- 1.5 HP

- Power Source

- Electric

- Weight (kg)

- Approx. 400 kg

- Dimension (L*W*H)

- 1150 x 800 x 2100 mm

- Capacity

- 32 mm drilling capacity in mild steel

- Color

- Green & Grey

- Usage & Applications

- Metalworking, drilling, tapping, reaming, boring operations in workshops and industries

- Spindle Taper

- MT-4

- Drilling Head Movement

- Horizontal and vertical head travel for versatility

- Arm Length

- 900 mm

- Base Size

- 900 x 600 mm

- Maximum Distance Spindle to Table

- 800 mm

- Lift Type

- Manual

- Maximum Distance Base to Spindle

- 1000 mm

- Chuck Capacity

- 316 mm

- No. of Spindle Speeds

- 8 steps

- Column Diameter

- 180 mm

32 MM Radial Drill Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 1 Week

- Packaging Details

- Gunny Bag, Pallet & Wooden Box.

- Main Export Market(s)

- Australia, Eastern Europe, Western Europe, Middle East, Central America, South America, Asia, North America, Africa

- Main Domestic Market

- All India

About 32 MM Radial Drill Machine

Technical Details:

| Type of Product | Radial Drilling Machine |

| Diameter of RAM | 78 mm |

| Spindle Travel | 260 mm |

| Drilling In M.S. | 32 mm |

| Column Dia. | 150 mm |

| Spindle Taper | M.T.4 |

| Box Table Dimension | 255x255x320 mm |

| Max / Min Distance Spindle Center to Column | 800-350 mm |

| Elevating Motor | 0.5 HP (1440 RPM) |

| Max / Min Distance Spindle Nose to Base | 900-170 mm |

| Lifting Motor V-Belt | A-22 |

| Drill-Head Motor | 2 HP (1440 RPM) |

| No of spindle speeds | 8 |

| Range of Spindle Speeds | 80-2600 RPM |

| Net Weight | 700 kg |

| Spindle feed by | Hand star lever and worm |

| working area of base | 790 x 690 mm |

| Overall height of machine | 1950 mm |

| V. Belt | B-47 |

| size of base | 1180x705x140 mm |

| Max Distance Spindle nose to Table | 650 mm |

Versatility for Workshop Operations

Equipped with horizontal and vertical head movement, the 32 MM Radial Drill Machine allows precise drilling from different angles. Its 900 mm arm length, adjustable arm, and 800 mm spindle-to-table reach support a variety of metalworking tasks, from standard drilling to complex boring and tapping projects.

Built for Durability and Precision

Constructed from stainless steel and cast iron, this radial drill machine promises long-term performance and minimal vibration. The machines high precision and sturdy build, combined with a low noise level, position it as a reliable solution for continuous workshop and industrial usage.

Ease of Operation and Maintenance

This model features a semi-automatic, manually controlled system for safe and straightforward usage. The machines adjustable arm and lift type, ergonomic layout, and easily accessible control points simplify daily operation and maintenance, enhancing productivity for both skilled operators and beginners.

FAQs of 32 MM Radial Drill Machine:

Q: How does the horizontal and vertical head movement benefit metalworking tasks?

A: The head movement in both horizontal and vertical directions allows the operator to position the drilling head exactly where needed, making it easier to work on large or awkwardly shaped workpieces. This capability increases the machines versatility and precision for tasks such as drilling, tapping, and boring at various angles.Q: What is the process for adjusting the arm and head of the 32 MM Radial Drill Machine?

A: To adjust the arm or head, simply release the manual clamps, position the arm horizontally or vertically as required, and lock it securely in place. The manual lift system ensures smooth movement, allowing for precise alignment with the workpiece for enhanced accuracy in drilling operations.Q: Where is the 32 MM Radial Drill Machine commonly used?

A: This radial drill machine is ideal for use in metalworking workshops, automotive manufacturing, fabrication units, and industrial facilities. Its robust build and flexible operation make it suitable for a variety of applications across Indian industries and export markets.Q: What are the main usage applications for this machine?

A: The machine is well-suited for drilling, tapping, reaming, and boring operations in mild steel and other metals. Its 32 mm drilling capacity and variable spindle speeds (8 steps) allow for high-precision work on different projects, from fast production jobs to intricate tasks.Q: When should regular maintenance be performed for optimal performance?

A: It is recommended to perform routine maintenancesuch as lubrication, inspection of moving parts, and checking electrical connectionsat regular weekly intervals or as advised in the operators manual. Proper upkeep ensures longevity and consistent performance.Q: What are the benefits of selecting the 32 MM Radial Drill Machine for industrial use?

A: Choosing this machine delivers multiple advantages, including high drilling precision, durable and low-noise construction, and an adjustable arm for greater flexibility. It also supports efficient operation and easy maintenance, resulting in improved productivity and reduced downtime for industrial users.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Radial Drill Machine Category

40 MM Radial Drill Machines

Price 85250 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel & Cast Iron

Product Type : Radial Drill Machine

Automatic Grade : SemiAutomatic

Power Source : Electric

75 MM Radial Drill Machine

Price 85200 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel & Cast Iron

Product Type : Radial Drill Machine

Automatic Grade : SemiAutomatic

Power Source : Electric

38 MM Radial Drill Machine

Price 85050 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel & Cast Iron

Product Type : Radial Drill Machine

Automatic Grade : SemiAutomatic

Power Source : Electric

25 MM Radial Drill Machines

Price 85000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel & Cast Iron

Product Type : Radial Drill Machine

Automatic Grade : SemiAutomatic

Power Source : Electric

Request A Quote

Request A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese