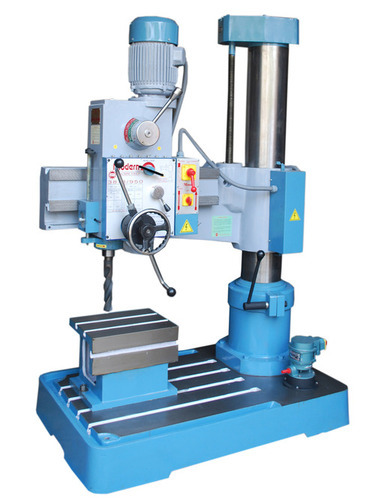

40 MM All Geared Radial Drill Machines

40 MM All Geared Radial Drill Machines Specification

- Frequency

- 50 Hz

- Diameter

- 40 mm

- Noise Level

- Low

- Table Size

- 500 x 500 mm

- Motor Power

- 2 HP

- Spindle Speed

- 8 Steps, 80-1800 RPM

- Cutting Area

- Up to 40 mm Diameter

- Condition

- New

- Machine Type

- All Geared Radial Drill Machine

- Features

- All Geared Transmission, High Rigidity, Adjustable Arm

- Product Type

- Drilling Machine

- Material

- Mild Steel & Cast Iron

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- CNC Or Not

- No

- Control System

- Manual

- Voltage

- 220-380 Volt (v)

- Power

- 2.2 kW

- Power Source

- Electric

- Weight (kg)

- 1100 kg

- Dimension (L*W*H)

- 1600 x 850 x 2200 mm

- Capacity

- 40 mm Drilling Capacity

- Color

- Standard / Grey

- Usage & Applications

- Heavy-Duty Drilling, Reaming & Tapping Operations

- Drilling Radius

- 1000 mm

- Column Diameter

- 170 mm

- Taper in Spindle

- MT 4

- Spindle Travel

- 250 mm

- Base Plate Size

- 1000 x 650 mm

- Distance from Spindle to Base

- 1000 mm

- Arm Lifting Motor

- 1 HP

- Swing

- 2000 mm

- Clamping Type

- Mechanical

- Distance from Spindle to Column

- 320 - 1000 mm

40 MM All Geared Radial Drill Machines Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 1 Week

- Packaging Details

- Gunny Bag, Pallet & Wooden Box.

- Main Export Market(s)

- Western Europe, Middle East, Central America, Eastern Europe, South America, Asia, North America, Australia, Africa

- Main Domestic Market

- All India

About 40 MM All Geared Radial Drill Machines

Technical Details:

| Drilling Capacity in Solid : | |

| Drilling in Steel | 40mm |

| Drilling in C.I. | 50mm |

| Tapping capacity in steel | 30mm |

| Boring in Steel | 90mm |

| Drilling in Head : | |

| Spindle travels [Manual] | 255mm |

| Spindle Taper | MT-4 |

| No. of Spindle Speeds/Range | 8/60 1760 RPM |

| RAM Diameter | 87mm |

| No. of Auto Feeds | 2 / 0.1 0.2 |

| Electrical: | |

| Power Supply | 415V, 3 PHASE, 50Hz |

| Electric Motor | 3 H.P., 1440/2800 RPM |

| Coolant Pump | 0 |

| Working Range : | |

| Max. dist. between spindle center to column face | 765mm |

| Max. dist. between spindle nose to Base Plate | 270/920mm |

| Max. dist. between spindle nose to working table | 190/700 mm |

| Column diameter | 500mm |

| Tilting working table | 130mm |

| Max. Vertical Traverse of Arm and with Table [manual] | 710mm |

| ROTATION OF ARM & BODY [BOTH SIDE] | 0-180 Deg. |

| General: | |

| Working Surface of Base Plate [L X W] | 535 X 520 |

| Working Surface of Table [Square] | 500 X 500 |

| Overall Size of machine | 1650 x 795 x 535 |

| No. of T-Slots & Nominal Size [Base & Table] | 2/13 |

| Base Size (Machined Area mm) | 535 x 798 |

| V-Belt Section | B 70 |

| Weight of machine(Approx.) | 575kg |

| Space Required by Machine: L x H x W: | |

| Space Required | 1300 x 1250 x 1800 |

| Colors: | |

| Colors | Maan Blue Special |

Advanced All Geared Transmission

Engineered with an all geared transmission system, this radial drill machine ensures seamless power transfer and steady torque during demanding drilling operations. The robust mechanism provides superior performance, reduces wear, and supports long-lasting reliability in heavy-duty usage, making it suitable for industrial workshops processing large workpieces.

High Precision & Adjustable Arm

This drill machine features a spindle with MT 4 taper and adjustable arm, allowing a spindle-to-base and spindle-to-column distance of up to 1000 mm. Such flexibility ensures accurate placement for diverse drilling tasks, accommodating different material sizes and enhancing overall operational precision.

Safety, Convenience, and Build Quality

Constructed from premium mild steel and cast iron, the machine guarantees stability and longevity. Its mechanical clamping system secures the workpiece firmly, while low noise operation and simple manual controls make it accessible and safe for operators in workshops and fabrication floors.

FAQs of 40 MM All Geared Radial Drill Machines:

Q: How is the 40 MM All Geared Radial Drill Machine operated?

A: This radial drill machine operates in a semi-automatic mode with manual control, allowing operators to adjust the arm, spindle, and speeds as required during the drilling process. It features a mechanical clamping system for quick and secure setup.Q: What types of materials and applications can this drill machine handle?

A: The machine is built for heavy-duty tasks such as drilling, reaming, and tapping, and can handle materials like mild steel and cast iron efficiently. It is ideal for workshops, manufacturing units, and fabrication industries needing high-precision operations.Q: When should I use the adjustable arm feature?

A: The adjustable arm is especially useful when you need to work on workpieces of varying sizes or require precise alignment for complex drilling operations, accommodating distances from spindle-to-column and spindle-to-base up to 1000 mm.Q: Where can this radial drill machine be installed?

A: With dimensions of 1600 x 850 x 2200 mm and a substantial weight of 1100 kg, this machine is best suited for industrial workspaces, workshops, and factory floors with adequate space and structural support.Q: What is the process for changing spindle speeds?

A: Spindle speeds can be adjusted in 8 steps ranging from 80 to 1800 RPM by using the gear selector. This allows you to fine-tune the speed to match different materials and drilling requirements for optimal results.Q: What benefits does the all geared transmission provide?

A: The all geared transmission minimizes power losses, delivers consistent torque, and ensures smooth operation even under heavy loads. This enhances efficiency, accuracy, and the longevity of the machine.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in All Geared Radial Drilling Machine Category

75mm all Geared Radial Drilling Machine

Price Range 200000.00 - 1200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Diameter : Maximum Drilling Diameter 75 mm

Frequency : 50 Hz

Power : 5 HP

Material : Stainless Steel & Cast Iron

50 MM All Geared Radial Drill Machines

Price Range 200250.00 - 1200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Diameter : Max Drilling Diameter 50 mm

Frequency : 50 Hz

Power : 2 to 3 kW

Material : Stainless Steel & Cast Iron

25 MM All Geared Radial Drill Machine

Price Range 200150.00 - 1200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Diameter : 25 mm

Frequency : 50 Hz

Power : 2 HP

Material : Stainless Steel & Cast Iron

32 MM All Geared Radial Drill Machine

Price Range 200100.00 - 1200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Diameter : 32 mm Maximum Drilling Diameter

Frequency : 50 Hz

Power : 2.2 kW (Approx)

Material : Mild Steel & Cast Iron

Request A Quote

Request A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese