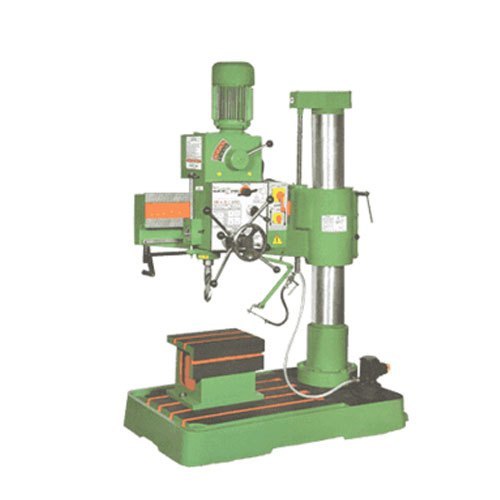

60mm All Geared Double Column Radial Drilling Machine

60mm All Geared Double Column Radial Drilling Machine Specification

- Motor Power

- 3HP

- Diameter

- 60mm

- Frequency

- 50 Hz

- Table Size

- Standard size

- Cutting Area

- Double Column

- Spindle Speed

- 400 RPM

- Dimension (L*W*H)

- Standard

- Machine Type

- Radial Drilling Machine

- Noise Level

- Low

- Condition

- New

- Features

- Heavy duty design reliable performance

- Product Type

- Drilling Machine

- Material

- Cast Iron Steel

- Automatic Grade

- Manual

- CNC Or Not

- Not CNC

- Control System

- All Geared

- Voltage

- 440V

- Power

- Electric

- Power Source

- AC

- Weight (kg)

- Approx. 1200 Kg

- Capacity

- 60mm

- Color

- Green

- Usage & Applications

- Drilling Industrial applications

About 60mm All Geared Double Column Radial Drilling Machine

Specification

Arm Elevating Motor | 2 HP |

Drilling Head Motor | 5 HP |

Number of Auto Feeds | 4/0.10 - 0.25 |

Number of Spindle | 16/40 |

Number of Spindle Speeds | 2000 RPM |

Spindle Travels | 325mm ( Auto/manual ) |

Model Name/Number | MAAN 60X16/1500 |

Precision Engineering with Robust Construction

Crafted from durable cast iron steel, the 60mm All Geared Double Column Radial Drilling Machine delivers excellent stability and strength. The double column structure supports heavy-duty drilling operations, reducing vibrations and ensuring precise results in industrial settings. Its heavy-duty design guarantees reliable and long-lasting performance.

Versatile Applications for Industrial Needs

This radial drilling machine is suitable for various industrial applications, including manufacturing, metalworking, and fabrication. The machine accommodates a standard table size, making it adaptable to diverse workpieces. With a 60mm drilling capacity, it is a trusted choice for workshops seeking efficiency and versatility.

FAQs of 60mm All Geared Double Column Radial Drilling Machine:

Q: How does the all-geared control system benefit the drilling operation?

A: The all-geared control system allows smoother and more reliable adjustment of spindle speed and feed, leading to precise drilling operations and reduced wear on gears. This system ensures greater control, making the machine easier and safer to operate in industrial environments.Q: What materials can I drill with this radial drilling machine?

A: This machine is constructed from cast iron steel and is designed to handle various materials typically encountered in industrial settings, including metals such as steel, aluminum, and cast iron, thanks to its robust design and 60mm drilling capacity.Q: Where is the ideal place to install this machine?

A: The 60mm All Geared Double Column Radial Drilling Machine is best suited for placement in industrial workshops or manufacturing plants with adequate space and electrical infrastructure. Ensure the area is stable and can support the machines approximate 1200 kg weight.Q: When is maintenance required for this drilling machine?

A: Regular maintenance should be performed according to usage frequency. It is recommended to inspect and lubricate moving parts periodically, check electrical components, and ensure all bolts are secure to maintain optimal performance and longevity.Q: What is the process for operating the manual model?

A: To operate the manual machine, position the workpiece on the standard table, adjust the spindle and settings using the all-geared control, and engage the drill at the desired speed (up to 400 RPM) using the AC-powered 3HP motor. Always follow safety protocols when drilling.Q: What are the main benefits of the double column design?

A: The double column structure provides exceptional rigidity and supports the drilling arm more effectively than single column machines, resulting in less deflection, improved accuracy, and reliable performance during heavy-duty drilling operations.Q: How does the low noise level improve industrial workflow?

A: A low noise level reduces operator fatigue, enhances comfort, and contributes to a safer working environment, enabling staff to work efficiently for longer periods while minimizing auditory distractions and potential hearing issues.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Drilling Machine Category

40mm All Geared Radial Drilling Machine

Condition : New

Features : Highquality build efficient drilling durable structure

Power Source : Electric

Material : Cast Iron/Steel

Color : Green

Usage & Applications : Industrial drilling applications

50mm All Geared Box Column Drilling Machine

Condition : New

Features : High speed precision drilling durable construction

Power Source : Electric

Material : Cast iron and steel

Color : Green

Usage & Applications : Industrial drilling applications

38mm All Geared Radial Drilling Machine

Condition : New

Features : Efficient Durable

Power Source : Electric Motor

Material : Cast Iron

Color : Green

Usage & Applications : Drilling in metal steel etc.

50mm All Geared Heavy Duty Radial Drilling Machine

Condition : New

Features : Heavyduty design precision drilling

Power Source : Electric

Material : Cast Iron

Color : Green

Usage & Applications : Industrial drilling applications

Request A Quote

Request A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese