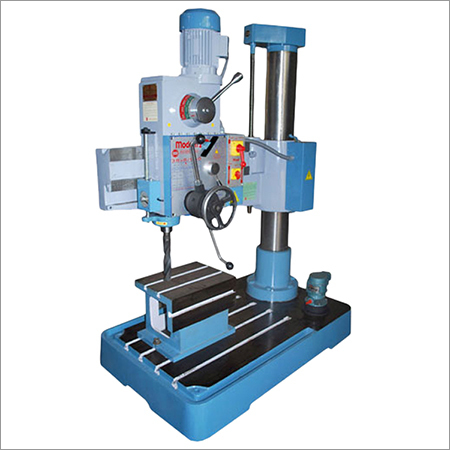

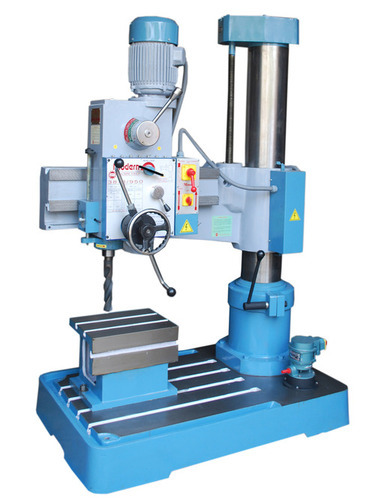

38 MM All Greared Radial Drill Machines

38 MM All Greared Radial Drill Machines Specification

- Motor Power

- 2 HP

- Features

- Heavy duty construction, Accurate drilling, Robust design, Adjustable radial arm

- Cutting Area

- 500 x 400 mm

- Noise Level

- Low

- Table Size

- 500 x 420 mm

- Condition

- New

- Frequency

- 50 Hz

- Machine Type

- All Geared Radial Drill

- Diameter

- 38 mm

- Spindle Speed

- 80 - 2000 RPM (Variable)

- Product Type

- Drilling Machine

- Material

- Stainless Steel & Cast Iron

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- CNC Or Not

- No

- Control System

- Manual

- Voltage

- 220-340 Volt (v)

- Power

- 2 HP

- Power Source

- Electric

- Weight (kg)

- Approx. 850 kg

- Dimension (L*W*H)

- 1800 x 900 x 2300 mm

- Capacity

- 38 mm drilling capacity

- Color

- Industrial Green & Black

- Usage & Applications

- Industrial Drilling, Workshop, Heavy Duty drilling, Metalworking

- Coolant Pump Included

- Yes

- Max Distance Spindle to Table

- 750 mm

- No. of Spindle Speeds

- 8

- Base Size

- 900 x 600 mm

- Spindle Taper

- MT4

- Drilling Depth

- 250 mm

- Spindle Feed

- 0.06/0.10/0.18 mm/rev

- Column Diameter

- 200 mm

- Max Distance Spindle to Base

- 1080 mm

- Radial Arm Travel

- 900 mm

38 MM All Greared Radial Drill Machines Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 1 Week

- Packaging Details

- Gunny Bag, Pallet & Wooden Box.

- Main Export Market(s)

- Western Europe, Australia, Eastern Europe, Middle East, Central America, South America, Asia, North America, Africa

- Main Domestic Market

- All India

About 38 MM All Greared Radial Drill Machines

Technical Details:

| Capacity: | |

| Capacity | 38mm |

| Drilling Capacity in Solid: | |

| In Steel having 600 Mpa Tensile Strengh | 38mm |

| In Cast Iron having 180BHN | 40mm |

| Tapping Capacity: | |

| Metric Threads up to size [MM] | |

| Any Other Threads [Inch] | Fine Pitch |

| Boring in Steel: | |

| Boring in Steel | 80mm |

| Drilling in Head: | |

| Taper in Spindle [Nose] | MT 4 |

| Spindle travels [Auto/Manual] | 200mm |

| Spindle Diameter at Front Bearing | 55mm |

| RAM Diameter | 78mm |

| No. of Spindle Speeds/Range | 8/60 1760 RPM |

| No. of Auto Feeds | 2/0.06 0.15 |

| Working Range: | |

| Max Drilling Radius | 1035 |

| Max Distance between Base Plate to Spindle [Spindle Retracted] | 240/1000 |

| Max Distance from Column Face to Spindle | 450/950 |

| Max Drilling Head Traverse | 500mm |

| Column Sleeve Diameter | 180mm |

| Vertical Traverse of Arm [Auto] | 750mm |

| Rotation of Arm [Both Side] | 1900mm |

| Height | 0-180 Deg. |

| Rapid Feeds: | |

| Travel of Rail [Vertical] | 750mm |

| Travel of Rail [Vertical] | 500 Manual |

| Electrical: | |

| Power Supply | 415V, 3 PHASE, 50Hz |

| Drilling Head Two Speed Motor | 2HP, 1440/2800 RPM |

| Arm Elevating Motor | 0.5HP, 1440 RPM |

| Coolant Pump | |

| Base Plate: | |

| Working surface: L x W | 800 x 660 |

| Overall size | 1300 x 800 x 170 R x S x Q |

| No. of T Slots & Nominal size | 01/04/16 |

| Weight with Electricals & Standard Accessories-APPROX | Net/Cross 800Kg |

| Space Required by Machine: L x W x H: | |

| Space Required | 1300 X 2600 X 1900 |

| Box Table Size: L x H x W: | |

| Box Table Size | 390 X 300 X 300 |

| Colors: | |

| Colors | MAAN Blue SPECIAL |

Precision Engineering and Robust Design

Built for reliability, this radial drill machine features a robust design with a sturdy 200 mm diameter column and a reinforced base. Its adjustable radial arm enables versatile drilling across a wide area, while advanced feed controls guarantee accurate results. With a maximum drilling capacity of 38 mm, users can confidently tackle both intricate and heavy-duty drilling jobs in demanding industrial environments.

Versatile Applications in Industrial Settings

Ideal for a range of applicationsworkshops, metalworking, and heavy-duty industrial drillingthe machine performs excellently thanks to its 8 spindle speeds and broad spindle-to-base/table distances. Its semi-automatic features allow for more efficient workflows. Manufacturers, exporters, and suppliers across India utilize this model for projects requiring consistent precision and adaptable operation.

User-Friendly and Efficient Operation

The 38 MM All Geared Radial Drill Machine offers manual control for maximum flexibility. Its equipped with a coolant pump for extended drilling runs, and its low noise operation ensures a comfortable workspace. The table size (500 x 420 mm) and cutting area (500 x 400 mm) make setup and adjustments straightforward, boosting both productivity and ease of use for professionals.

FAQs of 38 MM All Greared Radial Drill Machines:

Q: How does the adjustable radial arm enhance the drilling process on this machine?

A: The adjustable radial arm allows the drill head to move along a 900 mm travel range, enabling precise positioning over the workpiece. This flexibility accommodates various sizes and shapes, making complex and repetitive drilling processes more efficient.Q: What materials can the 38 MM All Geared Radial Drill Machine efficiently drill?

A: Thanks to its stainless steel and cast iron construction, variable spindle speeds, and robust motor, this machine can drill through metals such as steel, iron, and alloys, making it suitable for workshops and industrial metalworking operations.Q: When is it ideal to use the coolant pump included with the machine?

A: The integrated coolant pump should be used during extended or heavy-duty drilling sessions to prevent overheating, increase tool life, and ensure smooth cutting, especially when working with thicker or tougher materials.Q: Where can the machine be installed for optimum performance?

A: This radial drill machine is designed for industrial use and should be installed in spaces with stable electric supply (220-340 V), sufficient room for its dimensions (1800 x 900 x 2300 mm), and adequate ventilation for operation. Workshops, factories, and metalworking units are ideal settings.Q: What is the benefit of having eight spindle speeds available?

A: Offering eight spindle speeds (from 80 to 2000 RPM) allows operators to match the drilling speed to the material and job, improving accuracy, prolonging tool life, and ensuring optimal results across different tasks.Q: How is the drilling depth controlled and what is the maximum depth achievable?

A: The machine features feed controls and semi-automatic adjustments for precise depth management. Operators can achieve a maximum drilling depth of 250 mm, suitable for both shallow and deep industrial drilling applications.Q: What is the advantage of manual control over computerized systems for this drill machine?

A: Manual control provides direct adjustment and intervention during operation, allowing experienced users to respond quickly to changes in material or drilling requirements. This increases flexibility and reliability in environments where CNC control is unnecessary.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in All Geared Radial Drilling Machine Category

50 MM All Geared Radial Drill Machines

Price Range 200250.00 - 1200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 50 mm (Drilling) in Steel

Spindle Speed : 8 Steps, 622000 RPM

Power Source : Electric

Computerized : No

75mm all Geared Radial Drilling Machine

Price Range 200000.00 - 1200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : Drilling up to 75 mm diameter in steel

Spindle Speed : 60 1500 RPM (Variable in steps)

Power Source : Electric

Computerized : No

25 MM All Geared Radial Drill Machine

Price Range 200150.00 - 1200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 25 mm Drilling Capacity

Spindle Speed : 80 to 2000 RPM

Power Source : Electric

Computerized : No

40 MM All Geared Radial Drill Machines

Price Range 200300.00 - 1200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 40 mm Drilling Capacity

Spindle Speed : 8 Steps, 801800 RPM

Power Source : Electric

Computerized : No

Request A Quote

Request A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese