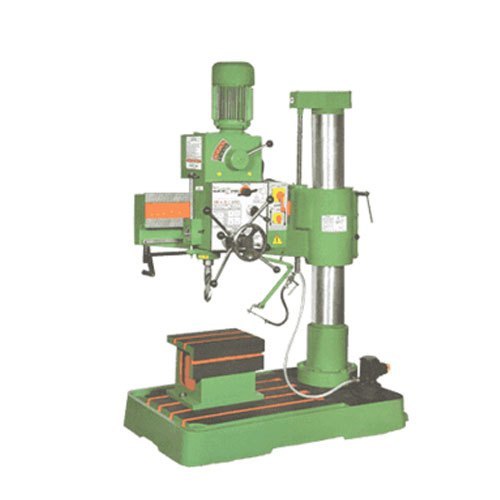

75mm Extra Heavy Duty All Geared Radial Drilling Machine

75mm Extra Heavy Duty All Geared Radial Drilling Machine Specification

- Condition

- New

- Diameter

- 75mm

- Machine Type

- Radial Drilling Machine

- Noise Level

- Low

- Features

- Extra Heavy Duty

- Product Type

- Radial Drilling Machine

- Material

- Metal

- Automatic Grade

- Automatic

- CNC Or Not

- Not CNC

- Control System

- All Geared

- Power Source

- Electric

- Capacity

- 75mm

- Color

- Green

- Usage & Applications

- Industrial Drilling Applications

About 75mm Extra Heavy Duty All Geared Radial Drilling Machine

Specification

Arm Elevating Motor | 3 HP |

Box Table Size | 600 x 500 x 500 mm |

Column Sleeve Diameter | 400 mm |

Distance Between Base Plate to Spindle | 500/1350 mm (Spindle Retracted) |

Drilling Capacity In Cast Iron | 80 mm (180 BHN ) |

Drilling Capacity In Steel | 70 mm ( Having 600 Mpa Tensile Strength) |

Drilling Head Motor | 7.5 HP |

Drilling Head Traverse | 1350 mm |

Drilling Radius | 500/1850 mm |

Number of T Slots And Nominal Size | 4/22 |

Overall Size | 2350 x 1060 mm |

Power Supply | 415V, 3Phase, 50Hz |

Rotation of Arm | 0-180 Degree |

Travel of Drilling Head | 1350 mm ( Horizontal ) |

Travel of Rail | 850 mm ( Vertical ) |

Vertical Traverse of Arm | 850 mm |

Weight of Machine with Electricals And Standard Accessories | 4500 Kg |

Working Surface | 1700 x 1060 mm |

Model Name/Number | 75X16/1800 |

Superior Performance for Industrial Drilling

This all geared radial drilling machine is built specifically for heavy-duty operations in industrial environments. The fully automatic setup and 75mm drilling capacity allow for continuous, high-precision work, meeting the rigorous demands of factories, workshops, and production units. Reliable, consistent, and made to deliver uncompromising results.

Robust Construction and Efficiency

Made entirely of premium-grade metal, this radial drilling machine ensures longevity and exceptional performance. The electric power source and all-geared control system provide smooth, efficient, and low-noise functioning, reducing maintenance and enhancing operator productivity.

FAQs of 75mm Extra Heavy Duty All Geared Radial Drilling Machine:

Q: How does the all geared control system benefit this drilling machine?

A: The all geared control system enables smooth speed adjustments, precise drilling operations, and minimal manual intervention. This system ensures higher operational efficiency, reduced wear and tear, and easy handling even during intensive use.Q: What applications is the 75mm Extra Heavy Duty Radial Drilling Machine best suited for?

A: This machine is designed for industrial drilling applications, particularly where heavy-duty and high-capacity drilling is required. It is ideal for manufacturing plants, metal fabrication workshops, and large-scale industrial settings requiring precision and durability.Q: When should I consider using this type of radial drilling machine?

A: You should choose this extra heavy-duty radial drilling machine when your operations demand frequent, large-diameter drilling in metal with minimum downtime and maximum consistency, especially in an automatic environment.Q: Where can the 75mm Extra Heavy Duty Radial Drilling Machine be purchased in India?

A: This model is available through reputable dealers, distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers across India. You can inquire with industrial machinery providers for availability and after-sales support.Q: What is the process for using this automatic radial drilling machine?

A: To operate, position the workpiece securely, adjust the gears for desired speed, and set the drilling parameters. The machines automatic controls allow for easy initiation and supervision of the drilling process, ensuring accurate and efficient results every cycle.Q: How does the low noise level of this machine enhance the work environment?

A: A low noise level contributes to a safer and more comfortable workplace, reducing operator fatigue and allowing for better communication and concentration during lengthy or multi-shift operations.Q: What are the key benefits of this extra heavy-duty radial drilling machine for industrial users?

A: Key benefits include high precision, robust performance, longevity, efficient all-geared operation, low noise, and the ability to handle heavy-duty, high-volume drillingmaking it a cost-effective and reliable choice for industrial users.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Drilling Machine Category

50mm All Geared Box Column Drilling Machine

Voltage : 220440V

Usage & Applications : Industrial drilling applications

Automatic Grade : Manual

CNC Or Not : Not CNC, Other

Material : Cast iron and steel

Features : High speed precision drilling durable construction

50mm All Geared Radial Drill Machine

Voltage : 415 V

Usage & Applications : Metalworking Drilling Precision Holes

Automatic Grade : SemiAutomatic

CNC Or Not : Other, Not CNC

Material : Cast Iron and Steel

Features : All Geared Design High Durability

60mm All Geared Double Column Radial Drilling Machine

Voltage : 440V

Usage & Applications : Drilling Industrial applications

Automatic Grade : Manual

CNC Or Not : Other, Not CNC

Material : Cast Iron Steel

Features : Heavy duty design reliable performance

38mm All Geared Radial Drilling Machine

Voltage : 220V

Usage & Applications : Drilling in metal steel etc.

Automatic Grade : SemiAutomatic

CNC Or Not : Not CNC, Other

Material : Cast Iron

Features : Efficient Durable

Request A Quote

Request A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese