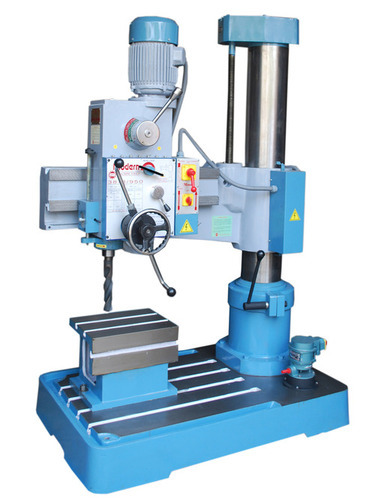

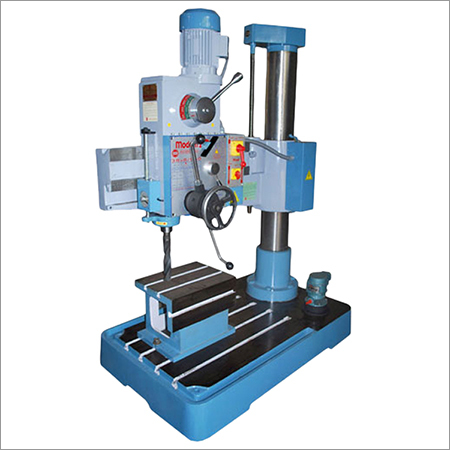

75 MM Radial Drill Machine

Price 85200 INR/ Unit

75 MM Radial Drill Machine Specification

- Features

- Rigid structure, High efficiency, Gear-driven spindle, Adjustable arm

- Table Size

- 500 x 500 mm

- Diameter

- Max. drilling dia. 75 mm

- Noise Level

- Low

- Machine Type

- Radial Drill Machine

- Spindle Speed

- 60 to 1200 RPM

- Cutting Area

- Suitable for medium to large size components

- Condition

- New

- Motor Power

- 5 HP

- Frequency

- 50 Hz

- Product Type

- Radial Drill Machine

- Material

- Stainless Steel & Cast Iron

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- CNC Or Not

- No

- Control System

- Manual

- Voltage

- 220-380 Volt (v)

- Power

- 5 HP

- Power Source

- Electric

- Weight (kg)

- 2100 kg

- Dimension (L*W*H)

- 1950 x 900 x 2450 mm

- Capacity

- 75 mm drilling capacity

- Color

- Blue & White

- Usage & Applications

- Drilling, Boring, Reaming, and Tapping of heavy workpieces

- Taper In Spindle

- MT 5

- Quill Travel

- 250 mm

- Radial Arm Length

- 1450 mm

- Max Distance Spindle To Column

- 1350 mm

- Base Size

- 1600 x 1000 mm

- Max Drilling Depth

- 250 mm

- Column Diameter

- 280 mm

- Max Distance Spindle To Base

- 1300 mm

- Build Quality

- Heavy Duty Construction

- Number of Spindle Speeds

- 8

- Coolant Pump

- Provided as standard

- Main Drive Motor

- 5 HP / 1440 RPM

75 MM Radial Drill Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 1 Week

- Packaging Details

- Gunny Bag, Pallet & Wooden Box.

- Main Export Market(s)

- Western Europe, Australia, Middle East, Central America, South America, Asia, Eastern Europe, North America, Africa

- Main Domestic Market

- All India

About 75 MM Radial Drill Machine

Technical Details:

| Capacity | 75mm |

| Drilling Capacity in Solid: | |

| In Steel having 600 Mpa Tensile Strength | 75mm |

| In Cast Iron having 180BHN | 85mm |

| Tapping Capacity: | |

| Metric Threads up to size [MM] | 48 X 3 |

| Any Other Threads [Inch] | 1 3/4 Fine Pitch |

| Boring in Steel: | |

| Boring in Steel | 160mm |

| Drilling in Head: | |

| Taper in Spindle [Nose] | MT 6 |

| Spindle travels [Auto/Manual] | 325mm |

| No. of Spindle Speeds/Range | 16/40 2000 RPM |

| No. of Auto Feeds | 4/0.10 0.25 |

| Working Range: | |

| Max Drilling Radius | 500/1800 |

| Max Distance between Base Plate to Spindle [Spindle Retracted] | 500/1400 |

| Max Drilling Head Traverse | 1350MM |

| Rotation of Arm [Both Side] | 0-180 Deg. |

| Electrical: | |

| Power Supply | 415V, 3 PHASE, 50Hz |

| Drilling Head Two Speed Motor | 7.5HP |

| Arm Elevating Motor | 3HP |

| Base Plate: | |

| Working surface: L x W | 1680 x 1060 |

| No. of T Slots & Nominal size | 4/22 |

| Weight with Electrical & Standard Accessories-APPROX (Net/Cross) | 5000/5500Kg |

| Wooden Box Packing Dimension: L x W x H | |

| Wooden Box Packing Dimension | 600 x 500 x 500 |

| Box Table Size: L x H x W: | |

| Box Table Size | |

| Colors: | |

| Colors | MAAN GREEN SPECIAL |

Robust Construction for Demanding Applications

This radial drill machine boasts a heavy-duty frame and gear-driven spindle, providing stability and accuracy in tough drilling operations. The combination of stainless steel and cast iron ensures durability and longevity, making it suitable for intensive industrial usage. Operators benefit from the rigid structure, which minimizes vibration and maximizes drilling precision for medium and large workpieces.

Flexible and Efficient Operation

With an adjustable radial arm (1450 mm) and eight selectable spindle speeds, the machine enables adaptability to various drilling needs. The spacious base (1600 x 1000 mm) and wide spindle reach (max. 1350 mm from column) accommodate large components, while the powerful 5 HP motor ensures effective processing. Semi-automatic features support streamlined workflow for repetitive operations.

Enhanced User Safety and Comfort

The machine is engineered to produce low noise and includes a standard coolant pump, protecting both the operator and the tool from overheating. The ergonomic manual controls and easy-access quill travel (250 mm) simplify operation, increasing efficiency without compromising safety. Heavy-duty construction further protects against wear and tear, reducing maintenance needs.

FAQs of 75 MM Radial Drill Machine:

Q: How does the 75 MM Radial Drill Machine ensure precision during drilling operations?

A: The machine achieves precision through its rigid construction, gear-driven spindle, and adjustable arm. These features minimize vibration and allow for accurate positioning and consistent drilling depth, even on large workpieces.Q: What type of materials can be processed using this radial drill machine?

A: This model is suitable for working with a variety of metals, particularly heavy and medium-sized components made from stainless steel, cast iron, or similar alloys. Its robust build and powerful motor enable efficient drilling, boring, reaming, and tapping in these materials.Q: When should the coolant pump be used during drilling?

A: The integrated coolant pump should be activated during extended drilling or when working with hard materials. It helps to maintain tool temperature, reduce friction, and prolong the lifespan of both the spindle and the cutting tool.Q: Where can this radial drill machine be installed?

A: Thanks to its heavy-duty design and large size, the machine is best suited for industrial environments, manufacturing facilities, fabrication workshops, and service centers dealing with medium to large workpieces.Q: What is the process for adjusting spindle speeds on this machine?

A: Operators can select from eight available spindle speeds, ranging from 60 to 1200 RPM, by manually changing gear settings. This allows adjustment to suit the material and application, optimizing efficiency and tool life.Q: How does the machine benefit users in terms of productivity?

A: Its high efficiency, wide operational range, semi-automatic grade, and ergonomic controls help users handle large volumes and diverse components quickly. The combination of adjustable arm, fast quill travel, and easy spindle speed selection contributes to reduced setup times and increased throughput.Q: What are the maintenance requirements for this radial drill machine?

A: Regular maintenance includes lubricating moving parts, checking the gear mechanism, ensuring the coolant system functions properly, and inspecting the spindle and electrical connections. Its heavy-duty construction and reliable components require minimal but consistent upkeep for optimal longevity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Radial Drill Machine Category

40 MM Radial Drill Machines

Price 85250 INR / Unit

Minimum Order Quantity : 1 Unit

Power Source : Electric

Material : Stainless Steel & Cast Iron

Product Type : Radial Drill Machine

Computerized : No

38 MM Radial Drill Machine

Price 85050 INR / Unit

Minimum Order Quantity : 1 Unit

Power Source : Electric

Material : Stainless Steel & Cast Iron

Product Type : Radial Drill Machine

Computerized : No

32 MM Radial Drill Machine

Price 85000 INR / Unit

Minimum Order Quantity : 1 Unit

Power Source : Electric

Material : Stainless Steel & Cast Iron

Product Type : Radial Drill Machine

Computerized : No

50 MM Radial Drill Machine

Price 85100 INR / Unit

Minimum Order Quantity : 1 Unit

Power Source : Electric

Material : Stainless Steel & Cast Iron

Product Type : Radial Drill Machine

Computerized : No

Request A Quote

Request A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese