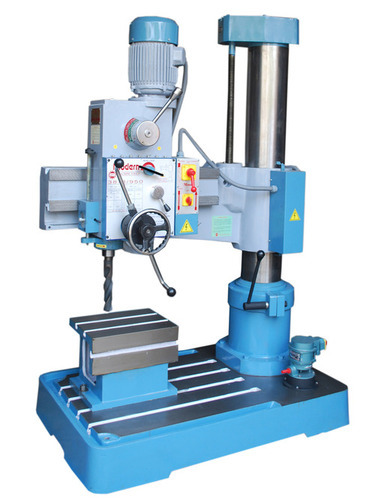

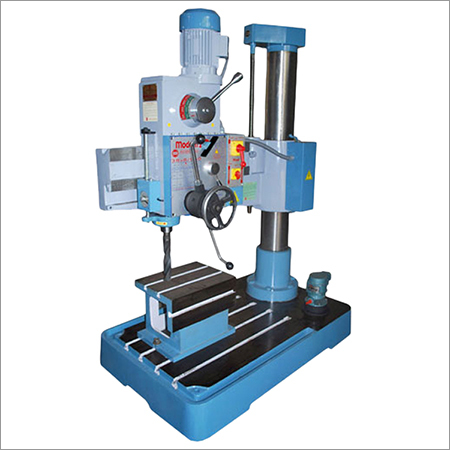

40 MM Radial Drill Machines

Price 85250 INR/ Unit

40 MM Radial Drill Machines Specification

- Table Size

- 700 x 500 mm

- Condition

- New

- Diameter

- Max. 40 mm

- Spindle Speed

- 70-2000 RPM (variable in steps)

- Noise Level

- Low (below 85 dB)

- Features

- Heavy-duty construction, adjustable arm, gear-driven feed, high precision

- Cutting Area

- Up to 40 mm diameter

- Machine Type

- 40 MM Radial Drill

- Frequency

- 50 Hz

- Motor Power

- 2 HP

- Product Type

- Radial Drill Machine

- Material

- Stainless Steel & Cast Iron

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- CNC Or Not

- No

- Control System

- Manual

- Voltage

- 220-380 Volt (v)

- Power

- 2-3 HP

- Power Source

- Electric

- Weight (kg)

- Approx. 800-1000 kg

- Dimension (L*W*H)

- 1600 x 800 x 2100 mm

- Capacity

- 40 mm drilling

- Color

- Standard Grey/Blue

- Usage & Applications

- Industrial drilling, metalworking shops, and fabrication workshops.

- Taper in Spindle

- MT-4

- Number of Speed Steps

- 8 or 12 Steps

- Arm Length

- 900 mm

- Base Size

- 900 x 600 mm

- Distance from Spindle to Column

- 950 mm

- Spindle Travel

- 250 mm

- Distance from Spindle to Base

- 1000 mm

- Main Column Diameter

- 170 mm

- Coolant System

- Provided

40 MM Radial Drill Machines Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 1 Week

- Packaging Details

- Gunny Bag, Pallet & Wooden Box.

- Main Export Market(s)

- Eastern Europe, Middle East, South America, Western Europe, Asia, Central America, North America, Australia, Africa

- Main Domestic Market

- All India

About 40 MM Radial Drill Machines

Salient Features of the machine are as under:

- Heavy Duty approximately 40mm drilling in steel.

- 2 auto feeds and 8 Spindle speeds for tapping, drilling, reaming operations.

- This appliance may be proficient of drilling, tapping, honing, milling, spot-facing, reaming, counter-boring, and boring and additional parallel utilities.

- Speeds can be effortlessly changed.

- Thread tapping processes can be ended in either gyration and employed depth can be measured by means of a positive stop gauge.

- Double Column Edifice for firmness and easy centering.

- Generously proportionate & well sufficiently ribbed base column, arm and plates for the extreme stiffness and the least deflection.

- The superior quality of this machinery and its affluence of procedure style it appropriate for utilizing by pupils, amateurs and hobbyists, and skilled technicians.

- Tapper Roller facility for improved descending of drill head on arm guide.

- Toughened and ground gears for smallest tear and wear.

- All gears are finished of nitride toughened, alloy steel, & lapped consecutively in oil bath installed with splined shafts.

- Precision toughened and ground spindle.

- Machine confirmed according to ISO: 2199-1982 Standards.

Technical Details:

| Capacity | 40/42mm |

| Drilling Capacity in Solid: | 50mm |

| IN CAST IRON HAVING 180BHN | 45mm |

| IN MILD STEEL HAVING 200Mpa TENSILE STRENGTH | 40mm |

| IN STEEL HAVING 600Mpa TENSILE STRENGTH | 42mm |

| Tapping Capacity: | |

| Tapping Capacity | |

| Drilling in Head: | |

| Taper in Spindle [Nose] | MT-4 |

| Spindle travels [Auto/Manual] | 200mm |

| No. of Spindle Speeds/Range | 8/50 1750 RPM |

| No. of Auto Feeds | 2/0.6 0.15 |

| Working Range: | |

| Max Drilling Radius | 1000mm |

| Max Distance between Base Plate to Spindle [Spindle Retracted] | 240/1000 |

| Max Drilling Head Traverse | 500mm |

| Column Sleeve Diameter | 750mm |

| Vertical Traverse of Arm [Auto] | 0-180 Deg. |

| Rotation of Arm [Both Side] | - |

| Electrical: | |

| Power Supply | 415V, 3 PHASE, 50Hz |

| Drilling Head Motor | 3HP |

| Arm Elevating Motor | 0.5HP |

| Base Plate: | |

| Working surface: L x W | 800 X 660 |

| Weight of machine with Electricals & Standard Accessories (Approx.)Net/Cross | 4/16 |

| Overall Size of machine | - |

| No. of T-Slots & Nominal Size [Base & Table] | 1400 x 1000 x 2000 |

| Wooden Box Pack Dimension: L x W x H: | |

| Wooden Box Pack Dimension | 400 X 300 X 300 |

High Precision Drilling for Industrial Demands

Designed to meet rigorous industrial requirements, this radial drill machine is ideal for metal fabrication and workshop applications. Heavy-duty construction, gear-driven feed, and adjustable arm ensure reliable performance and accuracy. The machine features an MT-4 spindle taper and variable speed settings, allowing for versatile use in drilling different metals up to 40 mm diameter. Its built-in coolant system maintains lower temperatures, contributing to safe and steady operations.

User-Friendly Operation and Maintenance

Operating the 40 MM Radial Drill Machine is straightforward due to its manual controls and semi-automatic grade. Maintenance is minimal owing to its sturdy materialsstainless steel and cast iron. The low noise level (below 85 dB) and efficient power source (electric) contribute to user comfort and safety during prolonged use. The machines compact dimensions and standard color options make it suitable for various workspace environments.

FAQs of 40 MM Radial Drill Machines:

Q: How is the 40 MM Radial Drill Machine typically used in industrial settings?

A: This machine is primarily used for precise drilling tasks in metalworking shops, fabrication workshops, and other industrial environments, making it suitable for large or heavy materials requiring up to 40 mm diameter drilling.Q: What benefits does the built-in coolant system offer during prolonged operation?

A: The coolant system helps maintain optimal temperature levels, reduces tool wear, and prevents overheating. This feature allows for longer, uninterrupted drilling sessions and enhances overall equipment longevity.Q: When should you select the variable speed steps during drilling?

A: Variable speed steps (8 or 12, ranging from 70 to 2000 RPM) should be chosen based on the material being drilled and the diameter required. Higher speeds are ideal for smaller, lighter materials, while lower speeds suit larger or tougher metals.Q: Where can the 40 MM Radial Drill Machine be installed or used?

A: The machine can be installed in industrial spaces such as workshops, fabrication plants, and metalworking shops across India, where robust and precise drilling capabilities are essential.Q: What is the process for adjusting the arm and spindle on this radial drill machine?

A: The adjustable arm and spindle are manually controlled, allowing users to set the position and height according to the workpiece. This flexibility accommodates varying sizes and shapes, ensuring accurate drilling.Q: How does the construction material enhance machine durability and performance?

A: Manufactured with stainless steel and cast iron, the machine resists corrosion and sustains robust operational demands. This heavy-duty build minimizes vibration and optimizes precision during drilling.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Radial Drill Machine Category

38 MM Radial Drill Machine

Price 85050 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220380 Volt (v)

Computerized : No

Material : Stainless Steel & Cast Iron

Product Type : Radial Drill Machine

32 MM Radial Drill Machine

Price 85000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220380 Volt (v)

Computerized : No

Material : Stainless Steel & Cast Iron

Product Type : Radial Drill Machine

75 MM Radial Drill Machine

Price 85200 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220380 Volt (v)

Computerized : No

Material : Stainless Steel & Cast Iron

Product Type : Radial Drill Machine

25 MM Radial Drill Machines

Price 85000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220380 Volt (v)

Computerized : No

Material : Stainless Steel & Cast Iron

Product Type : Radial Drill Machine

Request A Quote

Request A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese