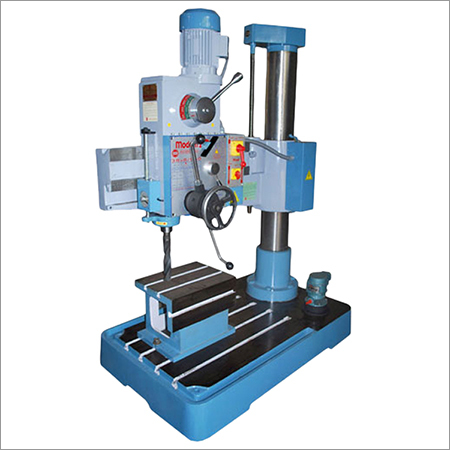

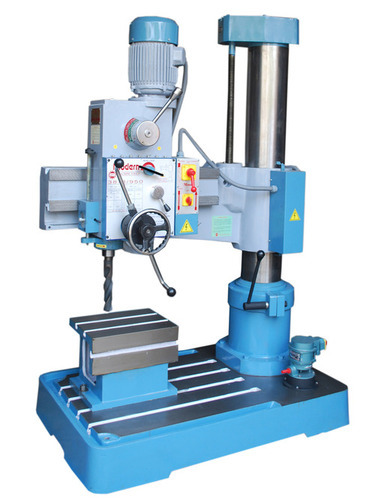

38 MM Radial Drill Machine

Price 85050 INR/ Unit

38 MM Radial Drill Machine Specification

- Table Size

- 500 x 800 mm

- Features

- High Precision, Heavy Duty Construction, Adjustable Arm, Durable Finish

- Frequency

- 50 Hz

- Motor Power

- 3 HP

- Condition

- New

- Spindle Speed

- 100-1800 RPM

- Diameter

- 38 mm

- Machine Type

- Radial Type

- Noise Level

- Low

- Cutting Area

- 500 x 800 mm

- Product Type

- Radial Drill Machine

- Material

- Stainless Steel & Cast Iron

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- CNC Or Not

- No

- Control System

- Manual

- Voltage

- 220-380 Volt (v)

- Power

- 2.2 kW

- Power Source

- Electric

- Weight (kg)

- 1050 kg

- Dimension (L*W*H)

- 1800 x 900 x 2200 mm

- Capacity

- 38 mm

- Color

- Green

- Usage & Applications

- Industrial Drilling, Metalworking, Fabrication Shops

- Tapping Capacity

- 25 mm

- Spindle Travel

- 250 mm

- Arm Length

- 1200 mm

- Number of Spindle Speeds

- 8

- Cooling System

- Integrated

- Distance Between Spindle and Base

- 600 mm

- Chuck Capacity

- 38 mm

- Distance Between Spindle and Column

- 320-1200 mm

- Column Diameter

- 170 mm

- Lubrication System

- Manual Lubrication

38 MM Radial Drill Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 1 Week

- Packaging Details

- Gunny Bag, Pallet & Wooden Box.

- Main Export Market(s)

- Western Europe, Middle East, Central America, Eastern Europe, South America, Asia, North America, Australia, Africa

- Main Domestic Market

- All India

About 38 MM Radial Drill Machine

By keeping track with the market development, we manufacture & supply 38 MM Radial Drill Machine. The high quality of this machine and its ease of operation make it ideal for use by students, amateurs' and home hobbyists, as well as skilled technicians. This Radial Drill Machine is featured with generously proportional & well adequately ribbed base plates, column and arm for maximum rigidity and minimum deflection. Customers can avail this 38 MM Radial Drill Machine on numerous specifications as per their requirements.

Features

- Machine tested as per IS: 2199-1982 Standards

- Hardened and ground spindle

- Easy installation

- Heavy Duty 38mm drilling in steel

Salient Features of the machine are as under:

- Heavy Duty about 38mm drilling in steel.

- Fine feed System and 8 Spindle speeds for drilling, reaming, tapping, operations.

- Six splined EN8 steel spindles successively in an arrangement of 4 bearings for providing rigidity and accuracy while drilling.

- MT-Bore is offered within grinded by interior grinding machine.

- Offers 8 Speeds by precise stable pairs of cone pulleys, that run on the two ball bearings.

- Spindle sleeve is correctly grinded and toughened is directed in improved, Drill head bore spindle is erected on five ball and bearing for flat and precise running.

- Arm and drill-head leader ways are exactly hand-scraped for the least play and inflexible fastening of drill-head with arm.

- By simple modification of only tapper wedge capability to fit the drill head on arm guide way.

- Gears manufactured from the excellent quality substance are helical teethed on introduced hobbling apparatus for hassle-free and noiseless running.

- Pillar & additional parts being offered in appliance are ground and ended by imported grinding machine.

- Grinding is offered on protector for revolving of radial arm to essential degree.

- Well adequately ribbed sordid plate, arm and arm bracket for supreme rigidity & the least deflection.

Technical Details:

| Capacity: | |

| Capacity | 38mm |

| Drilling Capacity in Solid: | |

| In Steel having 500 Mpa Tensile Strength | 38mm |

| In Cast Iron having 180BHN | 40mm |

| Tapping Capacity: | |

| Tapping Capacity | 30mm |

| Drilling in Head: | |

| Taper in Spindle - [Nose] | MT - 4 |

| Spindle travels | 250mm |

| No. of Spindle Speeds/Range | 8/50 - 1750 RPM |

| No. of Auto Feeds | Hand Feed(Fine Feed) |

| Electrical: | |

| Power Supply | 415V, 3 PHASE, 50Hz |

| Drilling Head Two Speed Motor | 2HP |

| Arm Elevating Motor | 0.5HP |

| Working Range: | |

| Max Drilling Radius | 1050mm |

| Max Distance between Base Plate to Spindle [Spindle Retracted] | 250/950mm |

| Max Drilling Head Traverse | 640mm |

| Vertical Traverse of Arm [Auto] | 750mm |

| Rotation of Arm [Both Side] | 0-180 Deg. |

| Base Plate: | |

| Working surface: L x W | 820 X 660 |

| Weight of machine with electrical & standard accessories(approx) Net/Cross | 850/1300kg |

| No. of T Slots & Nominal size | 4/16 |

| V-belt section of Arm Elevator Motor | A-25-A-24 |

| Box Table Size: L x H x W: | |

| Box Table Size | 400 X 300 X 300 |

| Wooden Box Packing Dimension | |

| Wooden Box packing Dimension | 1300 x 820 x 2000 |

High Precision Drilling

The radial drill machine offers accurate drilling performance with its adjustable arm, variable spindle speeds, and smooth table movement. Fabricators and metalworkers can achieve clean, precise cuts and tap holes up to 25 mm with minimal deviation, even on tough materials.

Durable Build for Heavy-Duty Applications

Constructed from premium stainless steel and cast iron, the machine is designed to withstand rigorous daily use in industrial environments. The heavy-duty frame, powerful 3 HP motor, and low noise output make it reliable for long-term service in manufacturing plants and workshops.

Versatile Functionality

With a sizeable table and support for various spindle distances, the 38 MM Radial Drill Machine adapts to diverse workpiece sizes and drilling requirements. Its manual control system grants operators full command over the process, ensuring tailored results for different fabrication jobs.

FAQs of 38 MM Radial Drill Machine:

Q: How does the 38 MM Radial Drill Machine enhance precision in industrial drilling jobs?

A: The machine is equipped with an adjustable arm and eight spindle speeds, allowing operators to set optimal parameters for different materials. Its robust construction and stable table ensure accurate positioning, resulting in high-precision drilling outcomes.Q: What types of materials can be processed with this drill machine?

A: Thanks to its heavy-duty build of stainless steel and cast iron and a chuck capacity of 38 mm, the machine can handle a wide range of metals such as steel, aluminum, and cast iron commonly found in fabrication and metalworking shops.Q: When should I use the manual lubrication system?

A: Manual lubrication should be applied regularly according to the manufacturers guidelines or when the machine is used intensively to ensure longevity and smooth operation of moving parts.Q: Where is this radial drill machine most commonly used?

A: It is ideal for use in industrial settings such as fabrication shops, metalworking plants, and manufacturing units. Its capacity and robust design suit environments where precision drilling and tapping are frequently required.Q: What is the process for adjusting spindle speed on this machine?

A: The machine features eight spindle speeds ranging from 100 to 1800 RPM. Speed adjustments are made manually using the machines control system, allowing operators to match speed settings with the material and drilling application.Q: How does the integrated cooling system benefit operation?

A: The built-in cooling system helps dissipate heat during extended drilling, protecting both the workpiece and machine components from overheating and ensuring consistent performance over long usage periods.Q: What advantages does the 38 MM Radial Drill Machine offer over standard drill presses?

A: Its adjustable radial arm, larger table size, and higher chuck capacity provide more versatility and accommodate bigger workpieces. The machines heavy-duty construction and precision features make it suitable for demanding industrial tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Radial Drill Machine Category

40 MM Radial Drill Machines

Price 85250 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Radial Drill Machine

Voltage : 220380 Volt (v)

Material : Stainless Steel & Cast Iron

Computerized : No

32 MM Radial Drill Machine

Price 85000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Radial Drill Machine

Voltage : 220380 Volt (v)

Material : Stainless Steel & Cast Iron

Computerized : No

75 MM Radial Drill Machine

Price 85200 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Radial Drill Machine

Voltage : 220380 Volt (v)

Material : Stainless Steel & Cast Iron

Computerized : No

50 MM Radial Drill Machine

Price 85100 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Radial Drill Machine

Voltage : 220380 Volt (v)

Material : Stainless Steel & Cast Iron

Computerized : No

Request A Quote

Request A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese