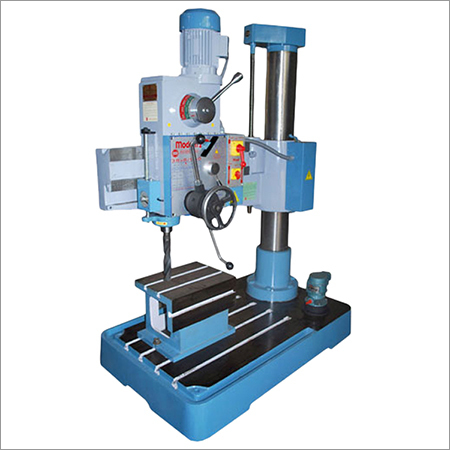

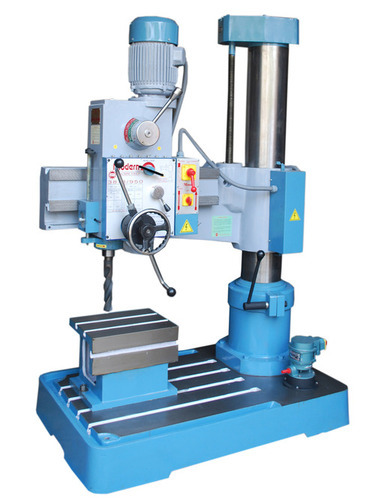

32 MM All Geared Radial Drill Machine

32 MM All Geared Radial Drill Machine Specification

- Table Size

- 480 x 380 mm

- Machine Type

- All Geared Radial Drill Machine

- Cutting Area

- Suitable for up to 32 mm diameter holes

- Frequency

- 50 Hz

- Noise Level

- Low

- Features

- All Geared, Radial Arm, Heavy Duty

- Condition

- New

- Motor Power

- 2 HP

- Diameter

- 32 mm Maximum Drilling Diameter

- Spindle Speed

- 80-1800 RPM (Variable)

- Product Type

- Drilling Machine

- Material

- Mild Steel & Cast Iron

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- CNC Or Not

- Not CNC

- Control System

- Manual Control Wheel

- Voltage

- 220-380 Volt (v)

- Power

- 2.2 kW (Approx)

- Power Source

- Electric

- Weight (kg)

- Approx. 850 kg

- Dimension (L*W*H)

- Approx. 1650 x 800 x 2150 mm

- Capacity

- 32 mm Drilling Capacity

- Color

- Industrial Blue & Grey

- Usage & Applications

- Metalworking, Industrial Drilling, Workshop Use

- Number of Spindle Speeds

- 8 Steps

- Arm Lifting Motor

- 0.75 HP

- Spindle Taper

- MT-4

- Distance from Spindle to Table

- Max. 1025 mm

- Distance from Spindle to Base

- Max. 1325 mm

- Coolant Pump

- Fitted

- Maximum Height of Drill

- 2150 mm

- Chuck Size

- 16 mm

- Installation

- Floor Mounted

- Column Diameter

- 180 mm

- Vertical Movement of Arm

- 540 mm

- Safety Features

- Emergency Stop Switch, Protective Shields

- Radial Arm Length

- 950 mm

32 MM All Geared Radial Drill Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 1 Week

- Packaging Details

- Gunny Bag, Pallet & Wooden Box.

- Main Export Market(s)

- Western Europe, Australia, Eastern Europe, Middle East, Central America, South America, Asia, North America, Africa

- Main Domestic Market

- All India

About 32 MM All Geared Radial Drill Machine

Technical Details:

| Type of Product | Radial Drilling Machine |

| Diameter of RAM | 78 mm |

| Spindle Travel | 260 mm |

| Drilling In M.S. | 32 mm |

| Column Dia. | 150 mm |

| Spindle Taper | M.T.4 |

| Box Table Dimension | 255x255x320 mm |

| Max / Min Distance Spindle Center to Column | 800-350 mm |

| Elevating Motor | 0.5 HP (1440 RPM) |

| Max / Min Distance Spindle Nose to Base | 900-170 mm |

| Lifting Motor V-Belt | A-22 |

| Drill-Head Motor | 2 HP (1440 RPM) |

| No of spindle speeds | 8 |

| Range of Spindle Speeds | 80-2600 RPM |

| Net Weight | 700 kg |

| Spindle feed by | Hand star lever and worm |

| working area of base | 790 x 690 mm |

| Overall height of machine | 1950 mm |

| V. Belt | B-47 |

| size of base | 1180x705x140 mm |

| Max Distance Spindle nose to Table | 650 mm |

Powerful and Versatile Drilling Solution

Engineered for industrial and workshop use, this 32 MM All Geared Radial Drill Machine delivers heavy-duty performance for precise and efficient metalworking. With a maximum drilling diameter of 32 mm, eight spindle speeds, and a robust 2 HP motor, the machine handles a wide range of drilling tasks, ensuring both efficiency and accuracy.

Designed for Safety and Reliability

Prioritizing user safety, the drill machine is equipped with an emergency stop switch, protective shields, and a securely mounted coolant pump. Constructed from mild steel and cast iron, the unit is durable and built to withstand continuous industrial use. Maintenance is straightforward, and the machine offers low operational noise for a comfortable working environment.

User-Friendly Features and Installation

The manual control wheel and semi-automatic functions make operation intuitive and manageable, even for less experienced users. Floor mounting ensures stability during heavy-duty applications, while the spacious table and adjustable spindle height accommodate various workpieces, enhancing flexibility across various drilling operations.

FAQs of 32 MM All Geared Radial Drill Machine:

Q: How does the all geared mechanism of this radial drill machine benefit industrial applications?

A: The all geared mechanism enables smooth, efficient power transmission and allows users to shift between eight precise spindle speeds (80-1800 RPM) effortlessly. This versatility is especially beneficial for industrial applications, ensuring optimal performance across varying materials and thicknesses, and enhancing productivity.Q: What materials and drilling capacities is this machine suitable for?

A: This drill machine is designed for metalworking, particularly in mild steel and cast iron. It supports drilling holes up to 32 mm in diameter, making it ideal for fabrication shops, workshops, and heavy industries requiring consistent, accurate drilling.Q: Where can this drilling machine be installed for optimal results?

A: The machine is floor-mounted for maximum stability and is best installed in workshops, factories, or any industrial environment with adequate space. Its robust design and approximate dimensions of 1650 x 800 x 2150 mm ensure it fits comfortably within most production floors.Q: What safety features are integrated into the machine?

A: Key safety features include an emergency stop switch and protective shields to safeguard the operator during use. Additionally, the fitted coolant pump helps prevent overheating, further ensuring a safe and stable operating environment.Q: How is the spindle movement and speed controlled?

A: Spindle movement is managed using the manual control wheel, while users can select from eight different spindle speed steps for varying drilling requirements. The vertical movement of the arm enables a maximum spindle-to-table distance of 1025 mm and spindle-to-base of 1325 mm, allowing for a wide range of workpiece sizes.Q: What is the process for maintaining this machine?

A: Regular maintenance involves checking the lubrication of gears, inspecting the coolant pump, and ensuring the emergency stop and protective shields are functional. Keeping the machine clean from debris and conducting routine inspections help preserve its performance and longevity.Q: What are the main advantages of choosing this radial drill for workshop use?

A: Choosing this machine offers several benefits, including heavy-duty capacity, low noise levels, flexible operating speeds, and enhanced safety features. Its durable build guarantees long-term performance, making it a reliable investment for workshops and industrial drilling operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in All Geared Radial Drilling Machine Category

75mm all Geared Radial Drilling Machine

Price Range 200000.00 - 1200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Machine Type : All Geared Radial Drilling Machine

Cutting Area : Up to 75 mm in diameter

Computerized : No

Table Size : 600 mm x 500 mm

38 MM All Greared Radial Drill Machines

Price Range 200350.00 - 1200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Machine Type : All Geared Radial Drill

Cutting Area : 500 x 400 mm

Computerized : No

Table Size : 500 x 420 mm

40 MM All Geared Radial Drill Machines

Price Range 200300.00 - 1200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Machine Type : All Geared Radial Drill Machine

Cutting Area : Up to 40 mm Diameter

Computerized : No

Table Size : 500 x 500 mm

50 MM All Geared Radial Drill Machines

Price Range 200250.00 - 1200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Machine Type : All Geared Radial Drill Machine

Cutting Area : 500 mm

Computerized : No

Table Size : 500 x 500 mm

Request A Quote

Request A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese