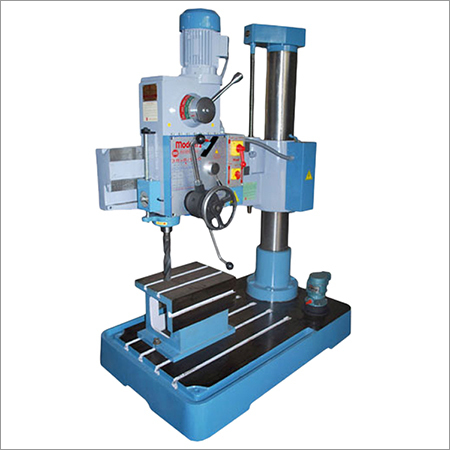

40 MM Auto Feed Radial Drill Machine

40 MM Auto Feed Radial Drill Machine Specification

- Frequency

- 50 Hz

- Machine Type

- Auto Feed Radial Drill Machine

- Features

- Auto feed, Heavy-duty design, High precision, Adjustable arm, Rigid base

- Table Size

- 560 x 400 mm

- Noise Level

- Low

- Spindle Speed

- 62 to 2000 RPM (variable)

- Cutting Area

- 410 mm Radial Arm

- Condition

- New

- Diameter

- 40 mm

- Motor Power

- 3 HP

- Product Type

- Drill Machine

- Material

- Stainless Steel & Cast Iron

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- CNC Or Not

- No

- Control System

- Manual Lever and Electrical Panel

- Voltage

- 220-280 Volt (v)

- Power

- 2.2 kW

- Power Source

- Electric

- Weight (kg)

- 1200 kg

- Dimension (L*W*H)

- 1630 x 820 x 2100 mm

- Capacity

- 40 mm Drilling Diameter

- Color

- Blue & White

- Usage & Applications

- Used for Drilling, Boring, Reaming, and Tapping operations on Metal and Heavy Engineering Components

- Number Of Spindle Speeds

- 8

- Maximum Drilling Depth

- 200 mm

- Vertical Travel Of Arm

- 600 mm

- Work Table Feed

- Automatic & Manual

- Spindle Taper

- MT-4

- Column Diameter

- 170 mm

- Arm Length

- 1100 mm

- Coolant Pump

- Included

40 MM Auto Feed Radial Drill Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 1 Week

- Packaging Details

- Gunny Bag, Pallet & Wooden Box.

- Main Export Market(s)

- Western Europe, Australia, Middle East, Central America, South America, Asia, Eastern Europe, North America, Africa

- Main Domestic Market

- All India

About 40 MM Auto Feed Radial Drill Machine

Technical Details:

| Capacity : | M.S. | C.I. |

| Drill Capacity | 40 mm | 40 mm |

| Drill Head : | ||

| Spindle nose | MT 4 | |

| Spindle Travel | 220 | |

| No. of Spindle Speed | 8 | |

| Range of Spindle Speed | 90 to 1000RPM | |

| Range of Power Feed | mm / Rev. | (2) 0.20-0.10 |

| Power : | H.P. | V. Belt |

| Drilling Motor | 1.5 | 1400KW/RPM |

| Arm Elevating Motor | 1 | 1400KW/RPM |

| Shipping Size Approx LxWxH | ||

| Working Range : | ||

| Drilling Radius Max./Min. | mm. | |

| Distance from column to Spindle Max./Min. | mm. | |

| Box Table LX WXH | mm. | 510x380x355 |

| Distance from Base to Spindle Max./Min | mm. | |

| Diametere of Column | mm. | 210 |

| Vertical Power movement of Arm | mm. | 750 |

| Base Plate : | ||

| L x W x H | mm. | 1800x900x180 mm |

| Working Surface | mm. | 1200x750 mm |

| No. of T-Slots | mm. | 4/16 mm |

Heavy-Duty Performance for Industrial Applications

Designed for demanding production environments, the 40 MM Auto Feed Radial Drill Machine supports multiple machining processes such as drilling, boring, reaming, and tapping. The heavy-duty construction and adjustable radial arm facilitate precise operations on large metal components, making it suitable for manufacturing plants, workshops, and engineering units.

Advanced Features Enhance Efficiency

Equipped with eight variable spindle speeds, an automatic feed system, and manual override, this radial drill ensures consistent output for intricate tasks. The built-in coolant pump improves tool life and the machines robust stainless steel and cast iron build provides stability and longevity through extensive usage.

User-Friendly Control and Safety

Manual lever operation coupled with an electrical control panel enables straightforward and safe handling. The rigid base and adjustable arm allow machinists to easily position components, while the noise reduction features and secure mounting contribute to a productive and safe work environment.

FAQs of 40 MM Auto Feed Radial Drill Machine:

Q: How can I use the 40 MM Auto Feed Radial Drill Machine for different metalworking processes?

A: You can perform drilling, boring, reaming, and tapping operations using this machine. The adjustable radial arm and MT-4 spindle taper allow easy tooling changes, while the variable speed settings optimize performance for each application on heavy engineering components.Q: What are the benefits of the automatic and manual feed options on the work table?

A: The automatic feed offers consistent machining results for repetitive tasks, enhancing production speed and accuracy. The manual feed allows for greater control during intricate operations, giving operators flexibility based on the complexity of the workpiece.Q: Where is the 40 MM Auto Feed Radial Drill Machine typically used?

A: This machine is ideal for manufacturing plants, metal fabrication workshops, and heavy engineering environments where high-precision drilling and related tasks are required on large or tough metal components.Q: When should the coolant pump be used during operation?

A: Activate the coolant pump when performing prolonged or high-speed drilling, boring, or tapping tasks. It helps dissipate heat, reduces tool wear, and maintains the integrity of both the machine and your workpiece.Q: What is the process for adjusting the arm and spindle speed?

A: Loosen the locking mechanism to adjust the 1100 mm arm to the desired position for your component. Spindle speed can be selected using the electrical control panel, offering eight speeds (62 to 2000 RPM) for optimized cutting based on material and operation type.Q: How does the semi-automatic control system benefit operators?

A: The semi-automatic system combines manual lever and electrical panel controls, allowing users to switch between automated and hands-on operations. This flexibility maximizes productivity and ensures user safety, especially for complex or varied tasks.Q: What are the main advantages of its heavy-duty design and materials?

A: Constructed from stainless steel and cast iron, the machine offers high durability, stability, and precision. Its rigid base reduces vibration and improves accuracy, even during intensive industrial machining sessions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Auto Feed Radial Drilling Machines Category

32 MM Auto Feed Radial Drill Machine

Price Range 200000.00 - 500000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220380 Volt (v)

Spindle Speed : 80 2400 rpm (variable)

Cutting Area : 32 mm diameter drilling

Usage & Applications : Industrial drilling, metal/wood fabrication, machinery workshops, job shops

65 MM Auto Feed Radial Drill Machine

Price Range 200200.00 - 500000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220480 Volt (v)

Spindle Speed : 751200 RPM (Variable 8 Steps)

Cutting Area : Radial reach up to 1200 mm

Usage & Applications : Drilling, tapping, reaming in heavy fabrication workshops and engineering industries

75 MM Auto Feed Radial Drill Machine

Price Range 200150.00 - 500000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220340 Volt (v)

Spindle Speed : 451500 RPM (variable)

Cutting Area : Up to 75 mm diameter

Usage & Applications : Suitable for metalworking, fabrication, heavy drilling in workshops and industrial environments

38 MM Auto Feed Radial Drill Machine

Price Range 200350.00 - 500000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220380 Volt (v)

Spindle Speed : 921800 RPM

Cutting Area : Variable (Depending on table adjustment)

Usage & Applications : Industrial Drilling, Workshop, Heavy Duty Drilling

Request A Quote

Request A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese