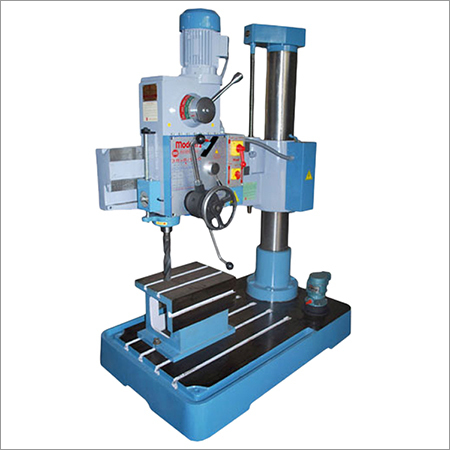

75 MM Auto Feed Radial Drill Machine

75 MM Auto Feed Radial Drill Machine Specification

- Diameter

- Maximum Drilling Diameter: 75 mm

- Frequency

- 50 Hz

- Condition

- New

- Spindle Speed

- 45-1500 RPM (variable)

- Noise Level

- Less than 85 dB

- Motor Power

- 4.5 HP

- Cutting Area

- Up to 75 mm diameter

- Features

- Auto feed, precision ground parts, robust body, adjustable arm, heavy-duty design

- Table Size

- 580 x 400 mm

- Machine Type

- Auto Feed Radial Drill Machine

- Product Type

- Drill Machine

- Material

- Mild Steel & Cast Iron

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- CNC Or Not

- No

- Control System

- Manual & Auto Feed Controls

- Voltage

- 220-340 Volt (v)

- Power

- 4.5 HP

- Power Source

- Electric

- Weight (kg)

- 2100 kg (approx.)

- Dimension (L*W*H)

- 1800 x 820 x 2400 mm

- Capacity

- 75 mm Drilling Capacity

- Color

- Machine Grey/Enamel Finish

- Usage & Applications

- Suitable for metalworking, fabrication, heavy drilling in workshops and industrial environments

- Column Diameter

- 220 mm

- Arm Length

- 1600 mm

- Number of Spindle Speeds

- 8

- Spindle Travel

- 250 mm

- Quill Diameter

- 75 mm

- Spindle Centre to Column (max)

- 1420 mm

- Work Table Movement

- 360 Rotatable

- Coolant Pump

- Fitted

- Lubrication System

- Centralized

- Taper in Spindle

- MT5

- Base Plate Size

- 1220 x 865 mm

- Main Shaft Bearing

- Timken/SKF (Heavy Duty)

- Distance Spindle to Base

- 800 mm (max)

75 MM Auto Feed Radial Drill Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 1 Week

- Packaging Details

- Gunny Bag, Pallet & Wooden Box.

- Main Export Market(s)

- Western Europe, Australia, Middle East, South America, Asia, Central America, Eastern Europe, North America, Africa

- Main Domestic Market

- All India

About 75 MM Auto Feed Radial Drill Machine

Technical Details:

| Capacity | 75mm |

| Drilling Capacity in Solid: | |

| In Steel having 600 Mpa Tensile Strengh | 75mm |

| In Cast Iron having 180BHN | 85mm |

| Tapping Capacity: | |

| Metric Threads up to size [MM] | 48 X 3 |

| Any Other Threads [Inch] | 1 3/4 Fine Pitch |

| Boring in Steel: | |

| Boring in Steel | 160mm |

| Drilling in Head: | |

| Taper in Spindle [Nose] | MT 6 |

| Spindle travels [Auto/Manual] | 325mm |

| No. of Spindle Speeds/Range | 16/40 2000 RPM |

| No. of Auto Feeds | 4/0.10 0.25 |

| Working Range: | |

| Max Drilling Radius | 500/1800 |

| Max Distance between Base Plate to Spindle [Spindle Retracted] | 500/1400 |

| Max Drilling Head Traverse | 1350MM |

| Rotation of Arm [Both Side] | 0-180 Deg. |

| Electrical: | |

| Power Supply | 415V, 3 PHASE, 50Hz |

| Drilling Head Two Speed Motor | 7.5HP |

| Arm Elevating Motor | 3HP |

| Base Plate: | |

| Working surface: L x W | 1680 x 1060 |

| No. of T Slots & Nominal size | 4/22 |

| Weight with Electrical & Standard Accessories-APPROX (Net/Cross) | 5000/5500Kg |

Powerful Performance for Heavy Drilling

Designed for demanding industrial applications, this radial drill machine blends a sturdy build with a 4.5 HP motor and up to 75 mm drilling diameter. The automatic feed and manual controls allow for versatile operation, making it an asset in workshops focused on high-precision tasks.

Versatile Arm and Work Table Functionality

With a 1600 mm adjustable arm, 800 mm spindle-to-base distance, and a 360 rotatable work table, this machine easily accommodates large and complex workpieces. Its flexibility allows for accurate drilling from various positions within its spacious work area.

Superior Durability and User Safety

Constructed from mild steel and cast iron, the radial drill features a centralized lubrication system and heavy-duty Timken/SKF bearings for long-lasting operation. Operating quietly under 85 dB, it provides a safe and ergonomic working environment for users.

FAQs of 75 MM Auto Feed Radial Drill Machine:

Q: How does the auto-feed system benefit the drilling process?

A: The auto-feed system streamlines drilling by automatically advancing the spindle at a consistent rate, improving accuracy and reducing operator fatigue during repetitive or deep drilling operations.Q: What types of applications is this machine suitable for?

A: This radial drill machine is ideal for metalworking, fabrication, heavy-duty drilling in workshops, and general industrial environments, particularly where precision and power are required.Q: When should I perform maintenance or lubrication on the machine?

A: Regular maintenance should follow the manufacturers guidelines, but thanks to its centralized lubrication system, essential components receive continuous lubrication, reducing the need for frequent manual intervention.Q: Where can this machine be installed for optimal performance?

A: It is best suited for industrial workshops or fabrication units with sufficient space (1800 x 820 x 2400 mm), a stable power supply (220-340 V), and proper floor support for its 2100 kg weight.Q: What is the process for changing spindle speeds?

A: Changing spindle speeds is straightforward, as the machine offers 8 variable speed options (45-1500 RPM) adjusted via its control panel, accommodating a wide range of materials and drilling tasks.Q: How does the machine ensure operator safety?

A: The machine operates at less than 85 dB for noise safety, includes a coolant pump to minimize heat, and features sturdy construction with heavy-duty bearings for operational stability and reduced risk of breakdowns.Q: What are the primary benefits of using this radial drill in my workshop?

A: Key benefits include high drilling capacity (up to 75 mm), automated and manual feed controls for versatility, reliable robust build, and the ability to drill at precise angles and positions, which enhances productivity and machining quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Auto Feed Radial Drilling Machines Category

38 MM Auto Feed Radial Drill Machine

Price Range 200350.00 - 500000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel & Cast Iron

Spindle Speed : 921800 RPM

Motor Power : 3 HP

Noise Level : 75 dB

50 MM Auto Feed Radial Drill Machine

Price Range 200250.00 - 500000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel & Cast Iron

Spindle Speed : 75 1225 RPM (variable)

Motor Power : 3 HP

Noise Level : Low

40 MM Auto Feed Radial Drill Machine

Price Range 200300.00 - 500000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel & Cast Iron

Spindle Speed : 62 to 2000 RPM (variable)

Motor Power : 3 HP

Noise Level : Low

32 MM Auto Feed Radial Drill Machine

Price Range 200000.00 - 500000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Mild Steel & Cast Iron

Spindle Speed : 80 2400 rpm (variable)

Motor Power : 3 HP

Noise Level : Below 75 dB

Request A Quote

Request A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese