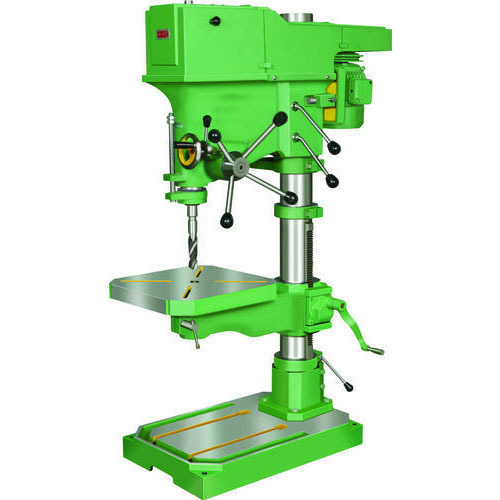

40mm All Geared Heavy Duty Pillar Drill Machine

Price 200000 INR/ Unit

40mm All Geared Heavy Duty Pillar Drill Machine Specification

- Noise Level

- Low

- Table Size

- 425 x 425 mm

- Condition

- New

- Frequency

- 50 Hz

- Spindle Speed

- 85 2150 RPM (8 or 12 steps)

- Cutting Area

- Up to 40 mm diameter

- Motor Power

- 1.5 kW

- Features

- Heavy duty geared drive, Accurate drilling, Rigid construction

- Machine Type

- All Geared Heavy Duty Pillar Drill

- Diameter

- 40 mm

- Product Type

- Pillar Drill Machine

- Material

- Cast Iron

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- CNC Or Not

- No

- Control System

- Manual

- Voltage

- 220 Volt (v)

- Power

- 2 HP

- Power Source

- Electric

- Weight (kg)

- 550 kg

- Dimension (L*W*H)

- 950 x 670 x 2150 mm

- Capacity

- 40 mm Drilling

- Color

- Blue & Silver

- Usage & Applications

- Industrial metal & wood drilling

- Spindle Nose Taper

- MT-4

- Column Diameter

- 130 mm

- Coolant Pump

- Optional

- Max. Spindle Travel

- 250 mm

- Distance from Spindle to Column

- 330 mm

- Distance from Spindle to Base

- 1175 mm

- Distance from Spindle to Table

- 700 mm

- V-Belt Drive

- All Geared

- Number of Speed Steps

- 8 or 12

- Base Size

- 700 x 480 mm

- Machine Finish

- Enamel Coated

- Drilling Capacity in Steel

- 40 mm

40mm All Geared Heavy Duty Pillar Drill Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 1 Week

- Packaging Details

- Gunny Bag, Pallet & Wooden Box.

- Main Export Market(s)

- Western Europe, Australia, Middle East, Central America, South America, Asia, Eastern Europe, North America, Africa

- Main Domestic Market

- All India

About 40mm All Geared Heavy Duty Pillar Drill Machine

For our esteemed clients, we manufacture & supply superb quality assortment of 40mm All Geared Heavy Duty Pillar Drill Machine. This machine is renowned for their sturdy construction and hassle free performance. Our machinery is designed to give maximum output and incur less maintenance. Besides, this 40mm All Geared Heavy Duty Pillar Drill Machine is widely utilized in various construction industries for drilling purposes. These machines are aesthetically designed and precision-engineered for their higher performance and durable work life.

Key Attributes:

- Single Column Construction

- High operational fluency

- Impeccable performance

- Speeds can easily change

Salient Features of the machine are as under:

- Heavy Duty: approximately 40mm drilling in steel.

- 2 auto feeds and 8 Spindle speeds for tapping, drilling, reaming operations.

- This machine is proficient of milling, drilling, tapping, counter-boring, honing, reaming, spot-facing, and boring and other parallel services.

- Speeds can be simply changed.

- Thread tapping processes can be completed in either working depth or rotation can be measured employing an optimistic stop gauge.

- Single Column Structure for obstinacy and easy centering.

- Openhandedly related & well sufficiently ribbed base column, plates, and arm for supreme stiffness and least rebound. The superior quality of this apparatus and its simplicity of process make it appropriate for use by amateurs, students, and home hobbyists, such as expert technicians.

- Toughened and ground mechanisms for least wear and tear

- All mechanisms are manufactured of nitride hardened, alloy steel and lapped running in oil bath fitted with splined shafts.

- Precision hardened and ground spindle.

- Machine examined according to IS: 2199-1982 Standards

Standard Accessories :

- Electrical consisting of two motors, contractors, limit switches, control transformers, wiring Etc.

Optional Accessories :

- Coolant Pump with Fitting

- Machine Lamp

- Drill Chuck with key & arbor

- Drill Sleeve

- Drill Vice

- Special T-Bolts

- Foundation Bolt

- Service Tool

- Wooden Box Packing & Forwarding

Technical Data :

| Drilling Capacity in Solid : | |

| Drilling in Steel | 40mm |

| Drilling in C.I. | 50mm |

| Tapping capacity in steel | 30mm |

| Boring in Steel | 90mm |

| Drilling in Head : | |

| Spindle travels [Manual] | 255mm |

| Spindle Taper | MT-4 |

| No. of Spindle Speeds/Range | 8/60 - 1760 RPM |

| RAM Diameter | 87mm |

| No. of Auto Feeds | 2 / 0.1 - 0.2 |

| Electrical: | |

| Power Supply | 415V, 3 PHASE, 50Hz |

| Electric Motor | 3 H.P., 1440/2800 RPM |

| Coolant Pump | 0 |

| Working Range : | |

| Max. dist. between spindle center to column face | 765mm |

| Max. dist. between spindle nose to Base Plate | 270/920mm |

| Max. dist. between spindle nose to working table | 190/700 mm |

| Column diameter | 500mm |

| Tilting working table | 130mm |

| Max. Vertical Traverse of Arm and with Table [manual] | 710mm |

| ROTATION OF ARM & BODY [BOTH SIDE] | 0-180 Deg. |

| General: | |

| Working Surface of Base Plate [L X W] | 535 X 520 |

| Working Surface of Table [Square] | 500 X 500 |

| Overall Size of machine | 1650 x 795 x 535 |

| No. of T-Slots & Nominal Size [Base & Table] | 2/13 |

| Base Size (Machined Area mm) | 535 x 798 |

| V-Belt Section | B - 70 |

| Weight of machine(Approx.) | 575kg |

| Space Required by Machine: L x H x W: | |

| Space Required | 1300 x 1250 x 1800 |

| Colors: | |

| Colors | Maan Green - Special |

Rigid Construction for Enhanced Precision

Manufactured using high-quality cast iron and finished with durable enamel coating, this pillar drill delivers unmatched rigidity and longevity. The robust 130 mm column diameter ensures stability during demanding operations, while the sturdy base and table offer ample support for a wide range of drilling tasks, minimizing vibration and enhancing accuracy.

Flexible Drilling Capacity and Speed Options

The machine offers a versatile 40 mm capacity in steel, expandable for other materials such as wood. It features 8 or 12 adjustable spindle speeds ranging from 85 to 2150 RPM, allowing users to tailor the drilling process based on material type and application. This flexibility translates to efficient, high-quality results in industrial environments.

Accurate, Low-Noise, Heavy-Duty Performance

Engineered for noise reduction, this model operates smoothly, even under continuous heavy loads. The all-geared mechanism ensures precise spindle movement and reliable power transmission, while the optional coolant pump can be added for extended use. These features collectively enable consistent output with minimal maintenance, perfect for high-volume drilling operations.

FAQs of 40mm All Geared Heavy Duty Pillar Drill Machine:

Q: How do I operate the 40mm All Geared Heavy Duty Pillar Drill Machine?

A: Operating the machine involves setting the desired spindle speed via the geared mechanism, securing your workpiece on the table or base, and manually engaging the spindle to drill. The semi-automatic control system and manual adjustments allow for precise positioning and feed rates.Q: What materials can this pillar drill machine handle?

A: This machine is primarily designed for drilling steel (up to 40 mm diameter), but it is also suitable for other metals, as well as wood, by adjusting the speed and using appropriate drill bits.Q: When should I consider using the coolant pump with this drill machine?

A: The optional coolant pump is recommended for prolonged or high-intensity drilling operations, especially in metals. It helps regulate the temperature, reduces tool wear, and maintains high accuracy during extended machining sessions.Q: Where is this drill machine commonly used?

A: The 40mm All Geared Heavy Duty Pillar Drill Machine is widely used in industrial workshops, fabrication units, manufacturing plants, and repair services across India for metal and wood drilling tasks.Q: What is the process for adjusting spindle speed?

A: Spindle speed adjustment is done by selecting from 8 or 12 geared steps between 85 and 2150 RPM. This is facilitated by the geared mechanism, allowing the user to optimize drilling speed for different materials and application requirements.Q: Can this machine be controlled by computer (CNC) or is it manual?

A: This model operates with a manual control system. It does not feature computerized (CNC) controls, making it suitable for skilled operators requiring hands-on adjustments and oversight.Q: What are the main benefits of using this pillar drill machine?

A: Key benefits include accurate drilling performance, heavy-duty construction for long-term durability, versatile speed options, low noise operation, and the ability to efficiently handle both metal and wood in industrial and workshop settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pillar Drill Machine Category

Box Column Drill Machine

Minimum Order Quantity : 1 Unit

Spindle Speed : 703220 RPM (Variable)

Motor Power : 0.75 kW

Condition : New

Power Source : Electric

All Geared Auto Feed Pillar Drill Machine

Price 41000 INR / Piece

Minimum Order Quantity : 1 Unit

Spindle Speed : Available in Multiple Options km/m

Motor Power : 1 HP VoltAmpere (VA)

Condition : New

Power Source : Electric

All Geared Pillar Drilling Machine

Spindle Speed : Multiple Speed Ranges

Motor Power : 1 HP

Condition : New

Power Source : Electric

75mm All geared Double column radial drilling machine

Price 3500000 INR / Piece

Minimum Order Quantity : 1 Piece

Request A Quote

Request A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese