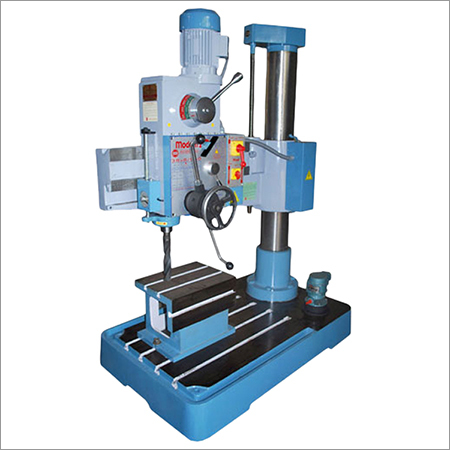

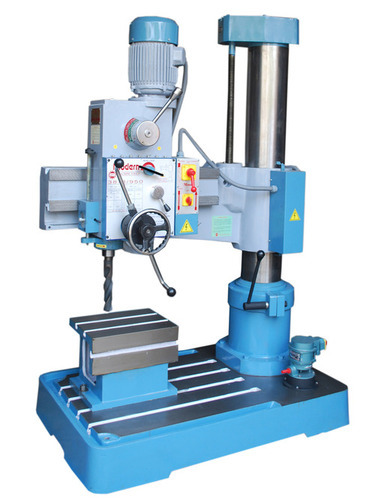

25 MM Radial Drill Machines

Price 85000 INR/ Unit

25 MM Radial Drill Machines Specification

- Product Type

- Radial Drill Machine

- Material

- Stainless Steel & Cast Iron

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Voltage

- 220-380 Volt (v)

- Power Source

- Electric

25 MM Radial Drill Machines Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 1 Week

- Packaging Details

- Gunny Bag, Pallet & Wooden Box.

- Main Export Market(s)

- Western Europe, Australia, Middle East, South America, Asia, Central America, Eastern Europe, North America, Africa

- Main Domestic Market

- All India

About 25 MM Radial Drill Machines

With our hard-earned experience in this domain, we manufacture & supply 25 MM RADIAL DRILL MACHINE. MT-Bore is provided internally grinded by internal grinding machine. The long columns offered in this machine gives maximum distance spindle nose to base. All cast parts are of fine close grained grey iron casting machined to close tolerance. The offered 25 MM RADIAL DRILL MACHINE is a large geared head drill machine, which can move along an arm attached to the machines column.

Features

- Hassle free performance

- Well adequately ribbed base plate

- Easy to install

- Required less maintenance

Salient Features of the machine are as under:

- Heavy Duty approximately 25mm drilling in steel.

- Fine feed System and 8 Spindle speeds for tapping, drilling, reaming operations.

- Six splined EN8 steel spindles consecutively in an arrangement of 4 bearings provides inflexibility and exactness while drilling.

- MT-Bore is offered inside grinded by interior grinding machine.

- Offers 8 Speeds by correct composed pairs of cone pulleys, that works on two ball bearings.

- Spindle sleeve is appropriately grinded and toughened is directed in honned also Drill head bore spindle is fitted on five ball & bearing for flat and precise running.

- Arm and drill-head leader ways are exactly hand-scraped for the least play and unbending fastening of drill-head along with arm.

- By simple change of only tapper wedge ability to arrange drill head on arm leader way.

- Gears manufactured from the excellent material are helical teethed on introduced hobbing machine for flat and noiseless running.

- Pillar & other shares being offered in machine are crushed and ended by introduced grinding machine.

- Grinding is offered on guard for spinning of radial arm to compulsory degree.

- Well sufficiently beamed base plate, arm & arm bracket for supreme inflexibility & minimum deflection.

- Elevator Pulley

- Box Table

- Electric Motor

- R/F Switch

- V-Belt

- Machine Vice

- Coolant Pump

- Drill Chuck / Arbur / Sleeve

- Wooden Box

- Special T Bolt

Specifications :

| Capacity : | |

| Capacity | 25mm |

| Drilling Capacity in Solid : | |

| In Steel having 600Mpa Tensile Strength | 25mm |

| In Cast Iron having 180BHN | 25mm |

| Tapping Capacity : | |

| Tapping Capacity | 20mm |

| Drilling in Head : | |

| Taper in Spindle -[Nose] | MT-3 |

| Spindle travels | 250mm |

| No. of Spindle Speeds/Range | 8/50 - 1800 RPM |

| Working Range : | |

| Max Drilling Radius | 765mm |

| Max Distance between Base Plate to Spindle [Spindle Retracted] | 270/920mm |

| Max Distance from Column Face to Spindle | 190/700 mm |

| Max Drilling Head Traverse | 500mm |

| Column Sleeve Diameter | 130mm |

| Vertical Traverse of Arm [Auto] | 710mm |

| Rotation of Arm [Both Side] | 0-180 Deg. |

| Base Plate: | |

| Working surface: L x W | 715 x 600 |

| Overall size | 990 x 600 x 140 |

| No. of T - Slots & Nominal size | 3/16 |

| General: | |

| V-Belt Section of Arm Elevator Motor | A - 24 / A - 23 |

| Weight of Machine with Standard Accessories (Approx) | Net / Cross 500 kg. |

| Box Table Size: L x H x W: | |

| Box Table Size | 300 X 210 X 210 |

| Colors: | |

| Colors | Maan Blue - Special |

Enhanced Drilling Efficiency

With its semi-automatic functionality and powerful electric motor, the 25 MM Radial Drill Machine streamlines drilling processes, reducing manual intervention while maintaining precision. Its steel and cast iron construction ensures a stable platform for accurate and consistent results on a variety of materials.

Versatility Across Applications

Suitable for small workshops, large manufacturing units, and export-focused enterprises, this machine serves multiple purposes. Whether you are involved in fabrication, assembly, or general maintenance, its 25 MM capacity meets the demands of diverse drilling applications in India.

FAQs of 25 MM Radial Drill Machines:

Q: How do I operate the 25 MM Radial Drill Machine safely?

A: Before operation, ensure the machine is properly grounded and connected to the specified 220380 volt power supply. Follow the manufacturers guidelines for setting up workpieces, adjusting the spindle, and using personal protective equipment. Use the semi-automatic controls to position and drill with precision.Q: What materials can be processed with this drill machine?

A: The 25 MM Radial Drill Machine is ideal for drilling through a range of materials, including metals such as stainless steel and cast iron, thanks to its robust construction and stable design.Q: When should I perform maintenance on this machine?

A: Regular maintenance should be conducted according to the manufacturers instructions or after every significant operational period. This includes lubricating moving parts, checking for wear or damage, and ensuring all electrical connections are secure.Q: Where is this machine commonly used in India?

A: This drill machine is widely utilized in various settings across India, such as fabrication workshops, manufacturing plants, garages, and by suppliers catering to the industrial sector.Q: What is the process for installing the 25 MM Radial Drill Machine?

A: Begin by placing the machine on a stable surface, ensuring proper leveling. Connect it to a compatible 220380 volt electric power source, secure all fittings, and conduct a preliminary test to verify all functions before commencing regular use.Q: What are the key benefits of using this semi-automatic drilling machine?

A: The semi-automatic design offers increased productivity, reduced user fatigue, and enhanced accuracy. Its durable steel and cast iron build also delivers long-term reliability and supports efficient operation in heavy-duty industrial tasks.Q: Who can supply or export this drill machine in India?

A: A broad network of dealers, distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers across India provide access to these radial drill machines, catering to businesses of all sizes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Radial Drill Machine Category

32 MM Radial Drill Machine

Price 85000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Radial Drill Machine

Computerized : No

Material : Stainless Steel & Cast Iron

Automatic Grade : SemiAutomatic

38 MM Radial Drill Machine

Price 85050 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Radial Drill Machine

Computerized : No

Material : Stainless Steel & Cast Iron

Automatic Grade : SemiAutomatic

75 MM Radial Drill Machine

Price 85200 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Radial Drill Machine

Computerized : No

Material : Stainless Steel & Cast Iron

Automatic Grade : SemiAutomatic

40 MM Radial Drill Machines

Price 85250 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Radial Drill Machine

Computerized : No

Material : Stainless Steel & Cast Iron

Automatic Grade : SemiAutomatic

Request A Quote

Request A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese