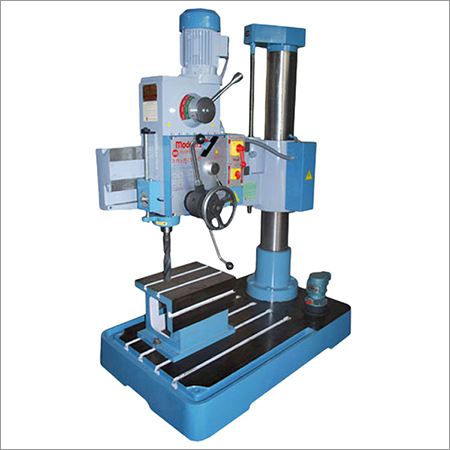

25 MM Semi All Geared Radial Drill Machines

25 MM Semi All Geared Radial Drill Machines Specification

- Spindle Speed

- 90 - 2800 rpm

- Frequency

- 50 Hz

- Machine Type

- Semi All Geared Radial Drill

- Motor Power

- 1.5 - 2 HP

- Diameter

- 25 mm

- Noise Level

- Low

- Cutting Area

- Variable as per material size

- Table Size

- 320 x 320 mm

- Condition

- New

- Features

- Heavy Duty Construction, Precision Gears, Easy Operation, Adjustable Arm

- Product Type

- Radial Drill Machine

- Material

- Stainless Steel & Cast Iron

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- CNC Or Not

- No

- Control System

- Manual

- Voltage

- 220-330 Volt (v)

- Power

- 1.5 - 2 HP

- Power Source

- Electric

- Weight (kg)

- Approx. 500-700 kg

- Dimension (L*W*H)

- 1200 x 900 x 2150 mm

- Capacity

- 25 mm drilling diameter in steel

- Color

- Industrial Blue & Silver

- Usage & Applications

- Drilling, Reaming, Tapping in metal sheets, precision engineering workshops

- Number of Spindle Speeds

- 8

- Spindle Travel

- 200 mm

- Max Distance Spindle to Base

- 910 mm

- Coolant System

- Available

- Arm Length

- 900 mm

- Taper in Spindle

- MT-3

- Min Distance Spindle to Base

- 350 mm

- Safety Features

- Overload Protection, Emergency Stop

- Clamping Type

- Manual Clamping

- Rotation of Arm

- 360 Degrees

- Column Diameter

- 170 mm

- Base Working Area

- 700 x 460 mm

- Feed Range

- 0.05 to 0.20 mm/rev

25 MM Semi All Geared Radial Drill Machines Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 1 Week

- Packaging Details

- Gunny Bag, Pallet & Wooden Box.

- Main Export Market(s)

- Australia, South America, Western Europe, Middle East, Central America, Asia, Eastern Europe, North America, Africa

- Main Domestic Market

- All India

About 25 MM Semi All Geared Radial Drill Machines

Technical Details:

| Capacity: | |

| Capacity | 25mm |

| Drilling Capacity in Solid: | |

| In Steel having 600 Mpa Tensile Strengh | 25mm |

| In Cast Iron having 180BHN | 25mm |

| Tapping Capacity: | |

| Tapping Capacity | 20mm |

| Drilling in Head: | |

| Taper in Spindle [Nose] | MT 3 |

| Spindle travels | 250mm |

| No. of Spindle Speeds/Range | 8/50 1800 RPM |

| Electrical: | |

| Power Supply | 415V, 3 PHASE, 50Hz |

| Drilling Head Two Speed Motor | 1.5HP |

| Arm Elevating Motor | 0.5HP |

| Coolant Pump | |

| Working Range: | |

| Max Drilling Radius | 765mm |

| Max Distance between Base Plate to Spindle [Spindle Retracted] | 270/920mm |

| Max Distance from Column Face to Spindle | 190/700 mm |

| Max Drilling Head Traverse | 500mm |

| Column Sleeve Diameter | 130mm |

| Vertical Traverse of Arm [Auto] | 710mm |

| Rotation of Arm [Both Side] | 0-180 Deg. |

| Base Plate: | |

| Working surface: L x W | 715 x 600 |

| Overall size | 990 x 600 x 140 |

| No. of T Slots & Nominal size | 3/16 |

| General: | |

| V-Belt Section of Arm Elevater Motor | A 24 / A 23 |

| Weight of Machine with Standard Accessories (Approx) | Net / Cross 500 kg. |

| Box Table Size: L x H x W: | |

| Box Table Size | 300 X 210 X 210 |

| Colors: | |

| Colors | MAAN Blue SPECIAL |

Heavy Duty & Reliable Operation

Made from stainless steel and cast iron, this radial drill machine offers strength and stability for demanding tasks. With a spindle travel of 200 mm and eight adjustable speeds up to 2800 rpm, users benefit from both precision and powerful drilling capability. The manual control system supports easy handling and flexible operation for varied applications.

Efficient Design & Safety Features

Designed with a 360-degree rotating arm and an adjustable working area, this model enhances user comfort and adaptability for complex drilling requirements. Integrated safety features, including overload protection and an emergency stop, minimize operational risks. Manual clamping further secures the setup, ensuring precise results every time.

FAQs of 25 MM Semi All Geared Radial Drill Machines:

Q: How do I operate the 25 MM Semi All Geared Radial Drill Machine for optimal precision?

A: Start by securely clamping your workpiece on the base using the manual clamping system. Adjust the arm and spindle position, select the desired speed from eight available spindle speeds, and ensure the coolant system is active for smooth drilling. Operate the machine via the manual control panel, maintaining consistent feed rate for maximum accuracy.Q: What are the primary applications of this radial drill machine?

A: This machine is ideal for drilling, reaming, and tapping in metal sheets. It is widely used in precision engineering workshops, metal fabrication units, and manufacturing industries for tasks requiring high accuracy and heavy-duty performance.Q: When should I use the coolant system during operation?

A: The coolant system should be activated whenever you perform continuous drilling or work with tough materials to prevent overheating. It helps extend tool life, improves finish quality, and minimizes thermal expansion during the drilling process.Q: Where can I install this machine in my workshop?

A: This radial drill machine is suitable for locations with adequate workspace, considering its dimensions of 1200 x 900 x 2150 mm and weight range of 500-700 kg. Ensure the installation spot has access to an appropriate electric power supply (220-330 Volt), stable flooring, and safe clearance for arm rotation.Q: What is the process for changing spindle speeds and feed rates?

A: Spindle speeds can be adjusted manually by selecting one of eight preset speed options. Feed rates are also adjustable within the 0.05-0.20 mm/rev range through the machines manual control mechanisms, allowing for tailored performance based on the material and drilling requirements.Q: What benefits does the overload protection and emergency stop feature offer?

A: The built-in overload protection and emergency stop features keep both the operator and the machine safe during unexpected events. They immediately halt operation in case of anomalies such as excessive load or emergency situations, reducing risk and safeguarding equipment longevity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Semi All Geared Radial Drill Machines Category

75 MM Semi All Geared Radial Drill Machines

Price Range 150100.00 - 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Radial Drill Machine

Material : Mild Steel & Cast Iron

Power Source : Electric

Automatic Grade : SemiAutomatic

38 MM Semi ALL Geared Radial Drill Machines

Price Range 150300.00 - 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Radial Drill Machine

Material : Mild Steel & Cast Iron

Power Source : Electric

Automatic Grade : SemiAutomatic

65 MM Semi All Geared Radial Drill Machine

Price Range 150150.00 - 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Radial Drill Machine

Material : Stainless Steel & Cast Iron

Power Source : Electric

Automatic Grade : SemiAutomatic

40 MM Semi All Geared Pillar Drill Machines

Price Range 150200.00 - 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Radial Drill Machine

Material : Mild Steel & Cast Iron

Power Source : Electric

Automatic Grade : SemiAutomatic

Request A Quote

Request A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese