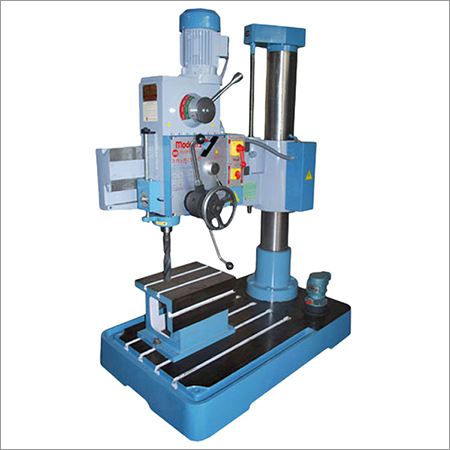

65 MM Semi All Geared Radial Drill Machine

65 MM Semi All Geared Radial Drill Machine Specification

- Machine Type

- Semi All Geared Radial Drill Machine

- Features

- Semi-geared design for high efficiency, durable construction, smooth operation, adjustable arm height, precision spindle

- Frequency

- 50 Hz

- Noise Level

- Low

- Motor Power

- 3 HP

- Spindle Speed

- 8 steps, 40 - 1800 RPM

- Cutting Area

- Large working area suitable for heavy-duty operations

- Table Size

- 500 x 500 mm

- Diameter

- 65 mm maximum drill diameter

- Condition

- New

- Product Type

- Radial Drill Machine

- Material

- Stainless Steel & Cast Iron

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- CNC Or Not

- No

- Control System

- Manual

- Voltage

- 220-340 Volt (v)

- Power

- 3-5 HP

- Power Source

- Electric

- Weight (kg)

- 1800 kg (approx)

- Dimension (L*W*H)

- 2300 x 950 x 2400 mm

- Capacity

- 65 mm drilling capacity

- Color

- Blue & White

- Usage & Applications

- Drilling, Boring, Reaming, & Tapping operations in workshop and fabrication industries

- Work Table Diameter

- 500 mm

- Distance from Spindle Center to Column

- 1350 mm

- Column Diameter

- 250 mm

- Main Drive Motor

- Standard ISI Marked

- Gear Box Type

- All Geared Head

- Coolant Pump

- Provided

- Taper in Spindle

- MT 5

- Spindle Feed

- 3 Auto Feeds

- Arm Length

- 1400 mm

- Arm Lifting Motor

- 0.5 HP

- Distance from Spindle Nose to Base

- 1250 mm

- Base Plate Size

- 1300 x 800 mm

- Spindle Travel

- 250 mm

- Distance from Spindle Center to Base

- 1250 mm

65 MM Semi All Geared Radial Drill Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 1 Week

- Packaging Details

- Gunny Bag, Pallet & Wooden Box.

- Main Export Market(s)

- Western Europe, Asia, Australia, South America, Eastern Europe, Middle East, Central America, North America, Africa

- Main Domestic Market

- All India

About 65 MM Semi All Geared Radial Drill Machine

Salient Features of the machine are as under :

- Heavy Duty approximately 65mm drilling in steel.

- 4 auto feeds and 16 Spindle speeds for tapping, drilling, reaming processes.

- This machine may be skilled of milling, tapping, drilling, counter-boring, honing, reaming, and boring, spot-facing, and other similar utilities.

- Speeds can be effortlessly altered.

- Thread tapping processes can be finished in either revolution and functioning deepness can be measured employing an optimistic stop gauge.

- Double Column Construction for severity and easy centering.

- Generously relational & well sufficiently ribbed base column, arm, plates, for supreme firmness and least deflection.

- The high excellence of this mechanism and its comfort of procedure manufactured it appropriate for use by scholars, home hobbyists, and amateurs' as well as expert technicians.

- Tapper Roller facility for improved descending of drill head on arm controller.

- Toughened and ground machineries for lowest wear and tear.

- All machineries are manufactured of nitride hardened, alloy steel, and lapped successively in oil bath snugged with splined shafts.

- Precision toughened and ground spindle.

- Arm and drill-head guiding customs are exactly hand scraped for tiniest play and rigid fastening of drill-head along with the arm.

- Machine confirmed according to ISO: 2199-1982 Standards

Technical Details:

| Capacity: | |

| Capacity | 65mm |

| Drilling Capacity in Solid: | |

| In Steel having 600 Mpa Tensile Strength | 65mm |

| In Cast Iron having 180BHN | 160mm |

| Tapping Capacity: | |

| Metric Threads up to size [MM] | 48 X 3 |

| Any Other Threads [Inch] | 1 3/4 Fine Pitch |

| Boring in Steel: | |

| Boring in Steel | 140mm |

| Taper in Spindle - [Nose] | MT - 5 |

| Spindle travels - [Auto/Manual] | 325mm |

| Spindle Diameter at Front Bearing | 78mm |

| RAM Diameter | 110mm |

| No. of Spindle Speeds/Range | 8/35 - 1230 RPM |

| No. of Auto Feeds | 4/0.10 - 0.25 |

| Working Range: | |

| Max Drilling Radius | 550/1600 |

| Max Distance between Base Plate to Spindle [Spindle Retracted] | 395/1420 |

| Max Drilling Head Traverse | 1100MM |

| Column Sleeve Diameter | 360mm |

| Vertical Traverse of Arm [Auto] | 725mm |

| Rotation of Arm [Both Side] | 0-180 Deg. |

| Height | 3100mm |

| Rapid Feeds: | |

| Travel of Rail [Vertical] | 725mm |

| Travel of Drilling Head [Horizontal] | 1100mm Manual |

| Electrical: | |

| Power Supply | 415V, 3 PHASE, 50Hz |

| Drilling Head Two Speed Motor | 6HP |

| Arm Elevating Motor | 2HP |

| Coolant Pump | - |

| Base Plate: | |

| Working surface: L x W | 1450 x 900 |

| Overall size | 2150 x 970 x 210[R x S x Q] |

| No. of T Slots & Nominal size | 4/22 |

| Weight with Electricals & Standard Accessories-APPROX | Net/Cross 4000Kg |

| Space Required by Machine: L x W x H: | |

| Space Required | 2600 x 2200 x 2750 |

| Box Table Size | 600 x 500 x 500 |

| Colors: | |

| Colors | MAAN GREEN - SPECIAL |

Efficient Drilling for Heavy-Duty Applications

The 65 MM Semi All Geared Radial Drill Machine combines versatile functionality with robust construction, supporting a maximum drilling capacity of 65 mm. Its adjustable arm, automatic spindle feeds, and 8-step variable spindle speeds provide excellent control for a wide range of material thicknesses and operations. Ideal for workshop and fabrication industries, it meets demanding operational requirements.

User-Friendly Design & Precision Control

This machine features a semi-geared head for high efficiency and low noise levels. The manual control system, coupled with a reliable 3 HP motor and automatic arm lifting, simplifies operation while maintaining precision. The large base plate and working area support heavy-duty workpieces, making setup and adjustments straightforward for operators.

Durable Build for Long-Term Performance

Manufactured from high-grade stainless steel and cast iron, the drill machine is engineered for strength and durability. The inclusion of a coolant pump ensures heat management during extended use, while the standard-compliant motor and gearbox guarantee consistent, safe performance. Its low-maintenance, semi-automatic design maximizes uptime in busy industrial settings.

FAQs of 65 MM Semi All Geared Radial Drill Machine:

Q: How does the semi-all geared mechanism benefit drilling operations?

A: The semi-all geared design provides smooth and efficient power transmission with minimal vibration, resulting in precise drilling, boring, reaming, and tapping. It allows for easy adjustment of spindle speed (8 steps between 401800 RPM) and smooth switching between operations for optimal results.Q: What are the main usage applications of this machine?

A: This radial drill machine is suitable for heavy-duty drilling, boring, reaming, and tapping tasks in workshops and fabrication industries. Its large cutting area and high capacity make it ideal for processing large workpieces in steel fabrication, manufacturing, and industrial maintenance.Q: When is this machine best to use over other drilling equipment?

A: Use this machine when handling large, heavy workpieces that require precision and variable spindle speeds. Its ability to handle up to 65 mm drill diameter and support for automatic spindle feeds make it preferable for demanding, repetitive jobs compared to lighter, less robust alternatives.Q: Where is the best place to install this machine in a workshop?

A: The machine should be placed on a level, sturdy surface with ample access surrounding the 2300 x 950 x 2400 mm footprint, ensuring easy loading and unloading of large workpieces. The installation area should also have proper electrical supply (220-340V, 50 Hz) and safety clearances.Q: What is the setup process for the 65 MM Semi All Geared Radial Drill Machine?

A: After positioning the machine, connect the electric supply, fill the coolant system, and verify all moving parts for smooth operation. Adjust the arm height using the 0.5 HP lifting motor, select the appropriate spindle speed, and secure the workpiece before initiating any operation.Q: How does the coolant pump enhance machine operation?

A: The provided coolant pump manages heat generated during drilling, especially in prolonged or heavy-duty use. This helps maintain tool life, ensures smooth cuts, and prevents material warping, contributing to both quality and efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Semi All Geared Radial Drill Machines Category

40 MM Semi All Geared Pillar Drill Machines

Price Range 150200.00 - 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power Source : Electric

Computerized : No

Voltage : 220320 Volt (v)

Material : Mild Steel & Cast Iron

25 MM Semi All Geared Radial Drill Machines

Price Range 150250.00 - 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power Source : Electric

Computerized : No

Voltage : 220330 Volt (v)

Material : Stainless Steel & Cast Iron

75 MM Semi All Geared Radial Drill Machines

Price Range 150100.00 - 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power Source : Electric

Computerized : No

Voltage : 220380 Volt (v)

Material : Mild Steel & Cast Iron

38 MM Semi ALL Geared Radial Drill Machines

Price Range 150300.00 - 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power Source : Electric

Computerized : No

Voltage : 220380 Volt (v)

Material : Mild Steel & Cast Iron

Request A Quote

Request A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese