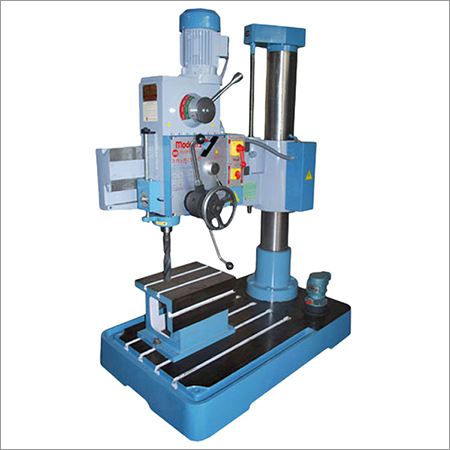

40 MM Semi All Geared Pillar Drill Machines

40 MM Semi All Geared Pillar Drill Machines Specification

- Motor Power

- 2 HP

- Table Size

- 400 x 400 mm

- Condition

- New

- Cutting Area

- Up to 40 mm diameter

- Noise Level

- 80 dB

- Features

- Gear driven, high precision, rigid structure, easy operation

- Frequency

- 50 Hz

- Diameter

- Maximum drilling diameter 40 mm

- Machine Type

- Pillar Drill Machine

- Spindle Speed

- 80 - 2100 rpm (variable)

- Product Type

- Radial Drill Machine

- Material

- Mild Steel & Cast Iron

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- CNC Or Not

- No

- Control System

- Manual

- Voltage

- 220-320 Volt (v)

- Power

- 2-3 HP

- Power Source

- Electric

- Weight (kg)

- 600-700 kg

- Dimension (L*W*H)

- 1250 x 700 x 2100 mm

- Capacity

- 40 mm

- Color

- Standard Grey with Blue Accents

- Usage & Applications

- Drilling, Reaming, Tapping in metal and wood industries

- Main Motor Type

- Induction motor

- Column Diameter

- 100 mm

- Quill Diameter

- 65 mm

- Work Table Movement

- Elevating & Rotating

- Number of Speed Steps

- 8

- Base Size

- 650 x 430 mm

- Spindle Taper

- MT-4

- Spindle Travel

- 250 mm

- Electrical Protection

- Yes, with overload relays

- Drill Head Movement

- Vertical & Horizontal adjustable

- Maximum Distance Spindle to Base

- 1000 mm

- Cooling System

- Provided (optional)

40 MM Semi All Geared Pillar Drill Machines Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 1 Week

- Packaging Details

- Gunny Bag, Pallet & Wooden Box.

- Main Export Market(s)

- Western Europe, Eastern Europe, Middle East, South America, Asia, Central America, North America, Australia, Africa

- Main Domestic Market

- All India

About 40 MM Semi All Geared Pillar Drill Machines

Technical Details:

| Capacity | 40/42mm |

| Drilling Capacity in Solid: | 50mm |

| IN CAST IRON HAVING 180BHN | 45mm |

| IN MILD STEEL HAVING 200Mpa TENSILE STRENGTH | 40mm |

| IN STEEL HAVING 600Mpa TENSILE STRENGTH | 42mm |

| Tapping Capacity: | |

| Tapping Capacity | |

| Drilling in Head: | |

| Taper in Spindle [Nose] | MT-4 |

| Spindle travels [Auto/Manual] | 200mm |

| No. of Spindle Speeds/Range | 8/50 1750 RPM |

| No. of Auto Feeds | 2/0.6 0.15 |

| Working Range: | |

| Max Drilling Radius | 1000mm |

| Max Distance between Base Plate to Spindle [Spindle Retracted] | 240/1000 |

| Max Drilling Head Traverse | 500mm |

| Column Sleeve Diameter | 750mm |

| Vertical Traverse of Arm [Auto] | 0-180 Deg. |

| Rotation of Arm [Both Side] | - |

| Electrical: | |

| Power Supply | 415V, 3 PHASE, 50Hz |

| Drilling Head Motor | 3HP |

| Arm Elevating Motor | 0.5HP |

| Base Plate: | |

| Working surface: L x W | 800 X 660 |

| Weight of machine with Electricals & Standard Accessories (Approx.)Net/Crooss | 4/16 |

| Overall Size of machine | - |

| No. of T-Slots & Nominal Size [Base & Table] | 1400 x 1000 x 2000 |

| Wooden Box Pack Dimension: L x W x H: | |

| Wooden Box Pack Dimension | 400 X 300 X 300 |

| Box Table Size: L x H x W: | |

| Box Table Size | - |

| Colors: | |

| Colors | MAAN Blue SPECIAL |

High-Precision Geared Mechanism

Designed for both metal and woodworking industries, the machines gear-driven system delivers superior precision and torque control. Its 8-speed settings and adjustable drill head enable flexibility for various drilling, reaming, and tapping tasks, catering to diverse production needs with high repeatability.

Flexible and Ergonomic Construction

Equipped with a 250 mm spindle travel, elevating and rotating work table, and a broad base, this pillar drill supports large and heavy workpieces. The manual but straightforward control system, combined with a semi-automatic grade, simplifies operations while ensuring safety and efficiency for users.

Durability and Operator Safety

Crafted from robust mild steel and cast iron, this machine promises a long lifespan. Electrical protection with overload relays prevents damage, and the optional cooling system helps maintain safe operating temperatures during intensive tasks. Standard noise levels (80 dB) and ergonomic adjustments support comfortable, safe use.

FAQs of 40 MM Semi All Geared Pillar Drill Machines:

Q: How does the vertical and horizontal drill head adjustment benefit the operator?

A: The vertical and horizontal adjustability of the drill head allows operators to position the tool precisely, enabling more complex drilling angles and making it easier to work on large or irregularly shaped materials. This flexibility also increases the range of possible applications without repositioning the entire workpiece.Q: What materials can be processed using this pillar drill machine?

A: The 40 MM Semi All Geared Pillar Drill Machine is engineered for both metal and wood applications. Its robust construction and spindle capacity allow it to bore, ream, and tap a variety of mild steel, alloys, and hardwood materials with reliable results.Q: When is the cooling system required during operation?

A: The optional cooling system is beneficial during extended or heavy-duty drilling sessions, especially when working with hard metals that generate substantial heat. It helps maintain optimal machine temperature, prolonging tool life and ensuring precise, distortion-free drilling results.Q: Where is this machine typically installed or used?

A: This drill machine is commonly installed in manufacturing units, fabrication workshops, maintenance facilities, and woodworking shops across India. Its versatility and capacity make it ideal for small to large-scale industrial settings.Q: What is the process for changing the spindle speed or operation mode?

A: Changing spindle speed is accomplished by adjusting the gear levers to one of eight available speed steps, which is straightforward due to the machines geared drive. All controls are manually operated, ensuring reliable speed transitions without complex programming or computerized parts.Q: How does electrical protection with overload relays enhance safety?

A: The integrated electrical protection system and overload relays are designed to automatically interrupt the power supply if excessive current or load is detected. This protects both the operator and the machine from electrical faults, damage, or overheating.Q: What are the main benefits of choosing a semi all geared pillar drill like this model?

A: This pillar drill combines high precision, gear-driven power, flexible operation, and durable construction. With easy manual adjustments, overload protection, and a wide drilling capacity, users gain consistent performance, operational safety, and long-term cost savings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Semi All Geared Radial Drill Machines Category

65 MM Semi All Geared Radial Drill Machine

Price Range 150150.00 - 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Automatic Grade : SemiAutomatic

Voltage : 220340 Volt (v)

Power Source : Electric

75 MM Semi All Geared Radial Drill Machines

Price Range 150100.00 - 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Automatic Grade : SemiAutomatic

Voltage : 220380 Volt (v)

Power Source : Electric

25 MM Semi All Geared Radial Drill Machines

Price Range 150250.00 - 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Automatic Grade : SemiAutomatic

Voltage : 220330 Volt (v)

Power Source : Electric

38 MM Semi ALL Geared Radial Drill Machines

Price Range 150300.00 - 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Automatic Grade : SemiAutomatic

Voltage : 220380 Volt (v)

Power Source : Electric

Request A Quote

Request A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese