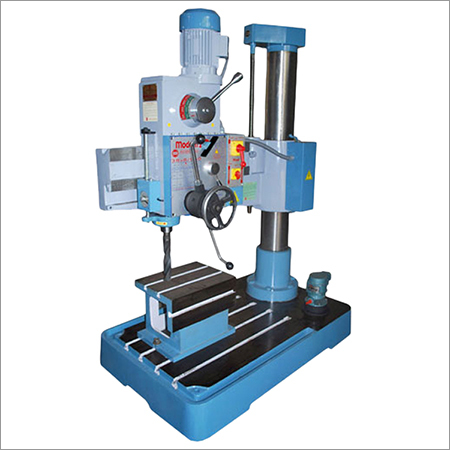

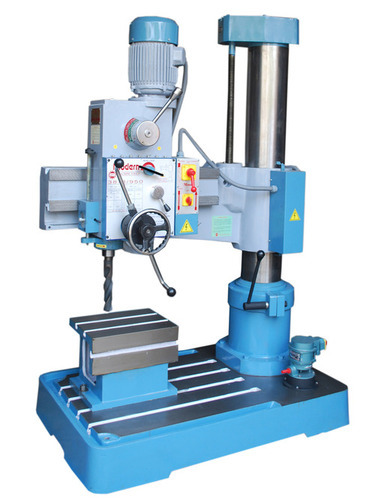

65 MM Radial Drill Machine

Price 85150 INR/ Unit

65 MM Radial Drill Machine Specification

- Product Type

- Radial Drill Machine

- Material

- Stainless Steel & Cast Iron

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Voltage

- 220-380 Volt (v)

- Power Source

- Electric

65 MM Radial Drill Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 1 Week

- Packaging Details

- Gunny Bag, Pallet & Wooden Box.

- Main Export Market(s)

- Australia, Western Europe, Middle East, Central America, South America, Asia, Eastern Europe, North America, Africa

- Main Domestic Market

- All India

About 65 MM Radial Drill Machine

Backed with a team of experienced professionals, we manufacture & supply Industrial Radial Drill Machine. Our machine has thread tapping operations that can be done in either rotation and working depth can be controlled using a positive stop gauge. This Industrial Radial Drill Machine may be capable of tapping, honing, counter-boring, spot-facing, drilling, milling, reaming, and boring and other similar utilities. The all gears are made of alloy steel, nitride hardened & lapped running in oil bath fitted with splined shafts.

Features

- Precision hardened and ground spindle

- Double Column Construction for Rigidity and effortless centering

- Arm guide Surfaces are Precision ground

- Changeable speed

Salient Features of the machine are as under:

- Heavy Duty 65mm drilling in steel.

- 16 Spindle speeds and 4 auto feeds for drilling, tapping, reaming operations.

- This machine may be Capable of drilling, milling, tapping, honing, counter-boring, spot-facing, reaming, and boring and other similar utilities.

- Speeds can easily change.

- Thread tapping operations can be done in either rotation and working depth can be controlled using a positive stop gauge.

- Double Column Construction for Rigidity and effortless centering.

- Generously Proportional & Well adequately ribbed base plates, column and arm for Maximum Rigidity and Minimum deflection.

- The high quality of this machine and its ease of operation make it suitable for use by students, amateurs and home hobbyists, as well as skilled technicians.

- Tapper Roller facility for better sliding of drill head on arm guide.

- Hardened and ground gears for minimum wear and tear.

- All gears are made of alloy steel, nitride hardened & lapped running in oil bath fitted with splined shafts.

- Precision hardened and ground spindle.

- Arm and drill-head guide ways are precisely hand scraped for minimum play and rigid clamping of drill-head with the arm.

- Machine tested as per ISO: 2199-1982 Standards

Standard Accessories :

Electrical consisting of two motors, contractors, limit switches, control transformers, wiring Etc

Optional Accessories :

- Box Table

- Coolant Pump with Fitting

- Machine Lamp

- Drill Chuck with key & arbor

- Drill Sleeve

- Drill Vice

- Special T-Bolts

- Foundation Bolt

- Service Tool

- Wooden Box Packing & Forwarding

Specification :

| Capacity : | |

| Capacity | 65mm |

| Driling Capacity in Solid : | |

| In Steel having 600Mpa Tensile Strength | 65mm |

| In Cast Iron having 180BHN | 160mm |

| Tapping Capacity : | |

| Metric Threads up to size [MM] | 48 X 3 |

| Any Other Threads [Inch] | 1 3/4 Fine Pitch |

| Boring in Steel : | |

| Boring in Steel | 140mm |

| Drilling in Head : | |

| Taper in Spindle -[Nose] | MT-5 |

| Spindle travels [Auto/Manual] | 325mm |

| Spindle Diameter at Front Bearing | 78mm |

| RAM Diameter | 110mm |

| No. of Spindle Speeds/Range | 8/35 1230 RPM |

| No. of Auto Feeds | 4/0.10 0.25 |

| Working Range : | |

| Max Drilling Radius | 550/1600 |

| Max Distance between Base Plate to Spindle [Spindle Retracted] | 395/1420 |

| Max Drilling Head Traverse | 1100MM |

| Column Sleeve Diameter | 360mm |

| Vertical Traverse of Arm [Auto] | 725mm |

| Rotation of Arm [Both Side] | 0-180 Deg. |

| Height | 3100mm |

| Rapid Feeds: | |

| Travel of Rail [Vertical] | 725mm |

| Travel of Drilling Head [Horizontal] | 1100mm Manual |

| Electrical: | |

| Power Supply | 415V, 3 PHASE, 50Hz |

| Drilling Head Two Speed Motor | 6HP |

| Arm Elevating Motor | 2HP |

| Coolant Pump | - |

| Base Plate: | |

| Working surface: L x W | 1450 x 900 |

| Overall size | 2150 x 970 x 210[R x S x Q] |

| No. of T Slots & Nominal size | 4/22 |

| Weight with Electrical & Standard Accessories-APPROX | Net/Cross 4000Kg |

| Space Required by Machine: L x W x H: | |

| Space Required | 2600 X 2200 X 2750 |

| Box Table Size: L x H x W: | |

| Box Table Size | 600 x 500 x 500 |

| Colors: | |

| Colors | Maan Green Special |

Robust Build for Industrial Use

Constructed from premium stainless steel and cast iron, the 65 MM Radial Drill Machine ensures reliable operation in demanding environments. Its sturdy structure offers excellent stability and longevity, even with heavy-duty usage.

Precision Drilling Made Efficient

With its semi-automatic functionality and adaptable voltage input (220-380V), the radial drill guarantees accurate and repeatable results. This makes it suitable for diverse industries where precision is crucial.

FAQs of 65 MM Radial Drill Machine:

Q: How does the 65 MM Radial Drill Machine improve drilling processes?

A: This radial drill machine streamlines drilling by allowing easy adjustment of the drill arm and spindle, enabling precise holes in large and complex workpieces. Its semi-automatic operation increases productivity and reduces manual errors.Q: What materials is the 65 MM Radial Drill Machine made from?

A: The machine is constructed using stainless steel and cast iron, ensuring durability, resistance to corrosion, and suitability for industrial environments.Q: When should I choose a semi-automatic radial drill over a computerized model?

A: Opt for the semi-automatic model when you require reliable manual control, robustness, and cost-effectiveness, especially in settings where computerized operation is not necessary.Q: Where is the 65 MM Radial Drill Machine commonly used in India?

A: It is widely utilized in manufacturing plants, fabrication workshops, metalworking units, and other industrial sectors across India for heavy-duty and precise drilling tasks.Q: What is the typical process for operating this drill machine?

A: Operation involves securing the workpiece, adjusting the drill arm to the desired position, setting the voltage, and activating the electric power source. Semi-automatic features assist in repetitive drilling operations.Q: How does the machine benefit dealers and suppliers in India?

A: Dealers and suppliers gain a reliable, high-demand product that appeals to a broad industrial customer base, thanks to its performance, durability, and accessible operation.Q: What are the power requirements for the 65 MM Radial Drill Machine?

A: The machine operates on an electric power source with a voltage range of 220-380V, making it compatible with standard industrial electrical systems in India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Radial Drill Machine Category

38 MM Radial Drill Machine

Price 85050 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel & Cast Iron

Voltage : 220380 Volt (v)

Power Source : Electric

Automatic Grade : SemiAutomatic

32 MM Radial Drill Machine

Price 85000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel & Cast Iron

Voltage : 220380 Volt (v)

Power Source : Electric

Automatic Grade : SemiAutomatic

75 MM Radial Drill Machine

Price 85200 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel & Cast Iron

Voltage : 220380 Volt (v)

Power Source : Electric

Automatic Grade : SemiAutomatic

40 MM Radial Drill Machines

Price 85250 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel & Cast Iron

Voltage : 220380 Volt (v)

Power Source : Electric

Automatic Grade : SemiAutomatic

Request A Quote

Request A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese