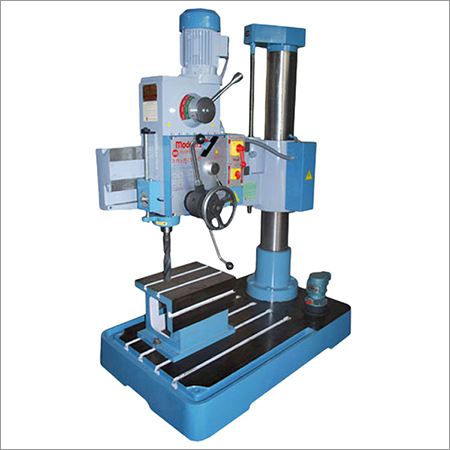

38 MM Semi ALL Geared Radial Drill Machines

38 MM Semi ALL Geared Radial Drill Machines Specification

- Table Size

- 450 mm x 350 mm

- Machine Type

- Semi All Geared Radial Drill Machine

- Diameter

- Max. 38 mm

- Spindle Speed

- 70-1800 RPM (Variable gears)

- Features

- High rigidity, gear driven operation, adjustable radial arm, robust construction

- Motor Power

- 2-3 HP

- Cutting Area

- Variable (depending on radial arm position)

- Condition

- New

- Frequency

- 50/60 Hz

- Noise Level

- Low

- Product Type

- Radial Drill Machine

- Material

- Mild Steel & Cast Iron

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- CNC Or Not

- No

- Control System

- Manual Lever/Gear Operation

- Voltage

- 220-380 Volt (v)

- Power

- 2.2 kW

- Power Source

- Electric

- Weight (kg)

- Approx. 1100 kg

- Dimension (L*W*H)

- 1900 mm x 850 mm x 2300 mm

- Capacity

- 38 mm Drilling Capacity in Steel

- Color

- Industrial Green/Blue (as per manufacturer)

- Usage & Applications

- Precision drilling in steel, cast iron and light metal components

- Column Diameter

- 200 mm

- Coolant System

- Provided

- Work Table Movement

- Manual

- Distance from Spindle to Table

- 650 mm (Max)

- Lifting Motor

- Provided

- Base Size

- 920 mm x 590 mm

- Spindle Taper

- MT-4

- Spindle Travel

- 250 mm

- Number of Spindle Speeds

- 8

- Radial Arm Rotation

- 360

- Distance from Spindle to Base

- 950 mm

38 MM Semi ALL Geared Radial Drill Machines Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 1 Week

- Packaging Details

- Gunny Bag, Pallet & Wooden Box.

- Main Export Market(s)

- Western Europe, Australia, Middle East, Central America, South America, Asia, Eastern Europe, North America, Africa

- Main Domestic Market

- All India

About 38 MM Semi ALL Geared Radial Drill Machines

Salient Features of the machine are as under:

- Heavy Duty about 38mm drilling in steel.

- 2 auto feeds and 8 Spindle speeds for tapping, drilling, reaming operations.

- This machinery is proficient of milling, tapping, drilling, counter-boring, honing, spot-facing, boring, reaming, and other parallel utilities.

- Speeds can be altered conveniently.

- Thread tapping processes can be completed in either revolution and employed depth can be measured employing a positive stop gauge.

- Single Column Building for inflexibility and easy centering.

- Openhandedly related & well sufficiently ribbed base column, plates, and arm for supreme rigidity and the least deflection.

- The supreme quality of this apparatus and its affluence of operation make it appropriate for utilizing by amateurs, students, and home hobbyists, also for skilled technicians.

- Tapper Roller facility for better sliding of drill head on arm guide.

- Toughened and ground gears for lowest wear and tear.

- All gears are manufactured of nitride hardened, alloy steel, & lapped successively in oil bath installed with splined shafts.

- Accuracy toughened and ground spindle.

- Arm and drill-head guide conducts are exactly hand scraped for the smallest play and unbending fastening of drill-head along with the arm.

- Machine verified according to ISO: 2199-1982 Standards

Technical Details:

| Capacity: | |

| Capacity | 38mm |

| Drilling Capacity in Solid: | |

| In Steel having 600 Mpa Tensile Strength | 38mm |

| In Cast Iron having 180BHN | 40mm |

| Tapping Capacity: | |

| Metric Threads up to size [MM] | - |

| Any Other Threads [Inch] | Fine Pitch |

| Boring in Steel: | |

| Boring in Steel | 80mm |

| Drilling in Head: | |

| Taper in Spindle - [Nose] | MT - 4 |

| Spindle travels - [Auto/Manual] | 200mm |

| Spindle Diameter at Front Bearing | 55mm |

| RAM Diameter | 78mm |

| No. of Spindle Speeds/Range | 8/60 - 1760 RPM |

| No. of Auto Feeds | 2/0.06 - 0.15 |

| Working Range: | |

| Max Drilling Radius | 1035 |

| Max Distance between Base Plate to Spindle [Spindle Retracted] | 240/1000 |

| Max Distance from Column Face to Spindle | 450/950 |

| Max Drilling Head Traverse | 500mm |

| Column Sleeve Diameter | 180mm |

| Vertical Traverse of Arm [Auto] | 750mm |

| Rotation of Arm [Both Side] | 1900mm |

| Height | 0-180 Deg. |

| Rapid Feeds: | |

| Travel of Rail - [Vertical] | 750mm |

| Travel of Rail - [Vertical] | 500 Manual |

| Electrical: | |

| Power Supply | 415V, 3 PHASE, 50Hz |

| Drilling Head Two Speed Motor | 2HP, 1440/2800 RPM |

| Arm Elevating Motor | 0.5HP, 1440 RPM |

| Coolant Pump | - |

| Base Plate: | |

| Working surface: L x W | 800 x 660 |

| Overall size | 1300 x 800 x 170 - R x S x Q |

| No. of T - Slots & Nominal size | 4/16 |

| Weight with Electricals & Standard Accessories-APPROX | Net/Cross 800Kg |

| Space Required by Machine: L x W x H: | |

| Space Required | 1300 X 2600 X 1900 |

| Box Table Size: L x H x W: | |

| Box Table Size | 390 X 300 X 300 |

| Colors: | |

| Colors | MAAN Blue - SPECIAL |

Outstanding Drilling Capacity and Adaptability

This semi all geared radial drill machine can handle up to 38 mm drilling capacity in steel, with variable spindle speeds and a fully adjustable radial arm. Operators benefit from effortless manipulation for jobs of varying sizes and materials, thanks to its robust construction and 360 rotation capability.

Precision and Efficiency for Industrial Applications

Designed for precise machining in steel, cast iron, and light metals, the machine excels in engineering workshops, fabrication units, and manufacturing facilities. The manual lever/gear control and semi-automatic features ensure tight tolerances, consistent quality, and reduced setup times.

FAQs of 38 MM Semi ALL Geared Radial Drill Machines:

Q: How is the 38 MM Semi All Geared Radial Drill Machine operated and controlled?

A: The machine uses a manual lever and gear operation system. Operators can manually adjust the work table, select from 8 spindle speeds, and use the radial arm rotation for flexible positioning during drilling tasks.Q: What types of materials can this drill machine process effectively?

A: This radial drill machine is engineered for precision drilling in steel, cast iron, and light metal components. Its robust design and powerful motor make it suitable for both heavy-duty and lighter machining operations.Q: When should you choose this radial drill machine over other models?

A: Choose this model when your application demands high drilling precision, variable spindle speeds, adjustable drilling positions, and efficient operation on a range of materials up to 38 mm in diameter. Its ideal for medium to large workshops and manufacturing environments.Q: Where can this machine be used within the manufacturing process?

A: It is suitable for use in fabrication shops, machining centers, maintenance workshops, and production lines across industries such as automotive, metalworking, and heavy engineering, wherever accurate and repeatable drilling is required.Q: What is the process for adjusting the drilling parameters on this machine?

A: Operators can set spindle speeds using the geared selector, control spindle travel up to 250 mm, adjust the height and rotation of the radial arm, and manually position the work table to match the job requirements. The controls are ergonomically designed for operator convenience.Q: How does the coolant system and lifting motor benefit the operator?

A: The integrated coolant system helps reduce heat and extend tool life, ensuring smooth and efficient drilling. The lifting motor aids in adjusting the radial arm effortlessly, allowing for swift changes in drilling position without manual strain.Q: What are the main benefits of choosing this model for industrial drilling?

A: Main benefits include high drilling accuracy, durable construction, low operational noise, flexible workpiece accommodation, and increased productivity thanks to semi-automatic features and easy manual adjustments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Semi All Geared Radial Drill Machines Category

75 MM Semi All Geared Radial Drill Machines

Price Range 150100.00 - 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Mild Steel & Cast Iron

Voltage : 220380 Volt (v)

Computerized : No

Automatic Grade : SemiAutomatic

65 MM Semi All Geared Radial Drill Machine

Price Range 150150.00 - 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel & Cast Iron

Voltage : 220340 Volt (v)

Computerized : No

Automatic Grade : SemiAutomatic

40 MM Semi All Geared Pillar Drill Machines

Price Range 150200.00 - 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Mild Steel & Cast Iron

Voltage : 220320 Volt (v)

Computerized : No

Automatic Grade : SemiAutomatic

25 MM Semi All Geared Radial Drill Machines

Price Range 150250.00 - 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel & Cast Iron

Voltage : 220330 Volt (v)

Computerized : No

Automatic Grade : SemiAutomatic

Request A Quote

Request A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese